A hybrid transfer station under construction in King County, Wash., aims to boost waste diversion.

January 13, 2012

By Karl Hufnagel, P.E., Science Applications International Corp.

The King County Department of Natural Resources and Parks, Solid Waste Division (SWD) is responsible for processing nearly 1 million tons of mixed municipal solid waste (MSW), organics, recyclables and household hazardous waste each year. The SWD’s core mission is to ensure that citizens have access to safe, reliable, efficient, environmentally sound and affordable solid waste handling and disposal services. To continue this mission, the county is constructing a new 2,500 ton-per-day solid waste transfer and recycling station with a strong focus on material diversion.

The King County Department of Natural Resources and Parks, Solid Waste Division (SWD) is responsible for processing nearly 1 million tons of mixed municipal solid waste (MSW), organics, recyclables and household hazardous waste each year. The SWD’s core mission is to ensure that citizens have access to safe, reliable, efficient, environmentally sound and affordable solid waste handling and disposal services. To continue this mission, the county is constructing a new 2,500 ton-per-day solid waste transfer and recycling station with a strong focus on material diversion.

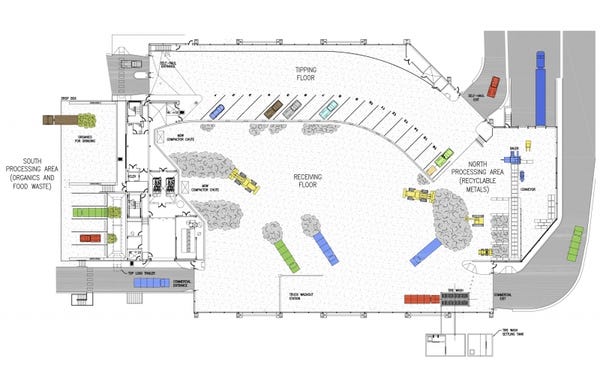

The new Bow Lake Recycling and Transfer Station will replace an existing maceration pit-type facility that opened in 1977 on an old landfill in Tukwila, Wash., about 10 miles south of Seattle. The center point of the 25-acre facility is the 70,000-square-foot transfer building seen in Figure 1.

Background

King County, which is slightly larger than the state of Delaware but with a population around 1.93 million, is a mixture of urban, suburban and rural communities. The county is the 14th most populous county in the country, ranks in the top 50 U.S. counties in per capita income and has a median household income of around $67,700 according to 2009 U.S. Census Bureau data.

The SWD serves unincorporated areas and 37 cities (not including Seattle and Milton, Wash.) through inter-local agreements and is undergoing a large capital improvement process that reflects a lengthy collaborative planning effort between the county and the cities.

The SWD serves unincorporated areas and 37 cities (not including Seattle and Milton, Wash.) through inter-local agreements and is undergoing a large capital improvement process that reflects a lengthy collaborative planning effort between the county and the cities.

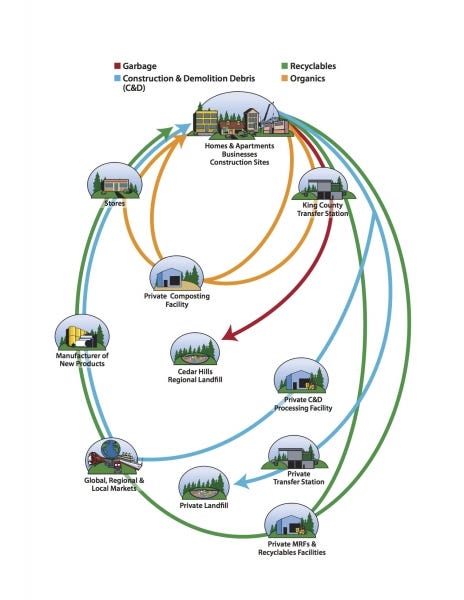

The solid waste system in King County is a long-standing partnership between the county and the private solid waste industry (see Figure 2). The county owns and operates eight transfer stations, two public convenience centers (drop box facilities) and the 940-acre Cedar Hills Regional Landfill. The county also operates a fleet of 56 trucks and 150 trailers that haul MSW to the landfill.

As new transfer stations are brought on-line, this fleet will also haul organics to privately operated processing facilities. Only a few of the eight stations currently have the capability to separately receive organics. Private firms provide curbside and business collection of MSW, organics (yard and food wastes), construction and demolition (C&D) debris, and recyclables and own and operate facilities for processing, transfer, and disposal, as well as C&D recovery, recyclable materials recovery and composting.

Reflecting its status as one of the larger counties in the country, the SWD processes a significant amount of waste throughout the year. In 2009, the following approximate quantities of materials passed through the county and private systems:

866,000 tons of MSW

252,00 tons of organics, including yard waste, food waste and compostable paper

620,000 tons of recyclable materials

235,000 tons of C&D materials

1,500 tons of moderate risk waste

Comprehensive Solid Waste Plan

In 2009 the county completed a Draft Comprehensive Solid Waste Plan that established a number of new waste prevention and recycling policies, including:

Achieve zero waste of resources (eliminate disposal of materials with economic value) by 2030.

Enhance, develop and implement waste prevention and recycling programs that will increase waste diversion using a combination of tools, including:

Infrastructure

Education and promotion

Incentives

Mandates

In addition to these policies, the plan included other recommendations, including maximizing recycling services at the county’s transfer facilities as new stations are constructed, with a focus on organics, clean wood, scrap metal and cardboard. The plan also set a number of waste prevention and recycling goals, including:

Achieve a recycling rate (measured at 47 percent in 2007) of 55 percent by 2015 and 70 percent by 2020.

Achieve a 15-percent reduction in waste generation from 2007 levels (14.2 pounds per person, residential, and 22.9 pounds per employee, commercial).

Bow Lake Recycling and Transfer Station

The existing Bow Lake Recycling and Transfer Station handles nearly one-third of the waste passing through the county’s transfer system, making it the most important of the county’s eight transfer stations. In 2009, the facility transferred around 270,000 tons of MSW and received a small quantity (around 2,300 tons) of self-hauled recyclables. It operates 362 days each year, 24 hours a day on weekdays and nine hours a day on weekends.

The existing Bow Lake Recycling and Transfer Station handles nearly one-third of the waste passing through the county’s transfer system, making it the most important of the county’s eight transfer stations. In 2009, the facility transferred around 270,000 tons of MSW and received a small quantity (around 2,300 tons) of self-hauled recyclables. It operates 362 days each year, 24 hours a day on weekdays and nine hours a day on weekends.

The existing station (see Figure 3) is an open-sided facility with a central maceration pit occupying eight acres of an old landfill site.

Because of its importance within the county’s system, operation of the existing station must be maintained while the new station is constructed adjacent to, and eventually on top of, the footprint of the existing facility, which will be demolished in a later phase of the construction. This need to maintain service at the Bow Lake site greatly complicated the planning and design of the new station and contributes to the unusually long five-year, multi-phase construction period.

Material Diversion

What really sets this station apart from its sister stations in King County, and from most transfer stations around the country, is that the tipping and receiving floor includes a purpose-designed recovered material sorting, holding, baling and load-out area. This 10,000-square-foot processing area is located at the opposite end of the station from where the MSW is loaded out, as seen in Figure 4, and is designated as the North Processing Area.

The SWD estimates that about 6 to 8 percent of the current 270,000 tons-per-year of waste processed through the Bow Lake station could practicably be separated and diverted for recycling and reuse. The Bow Lake station serves a large industrial, commercial and warehouse area of the county in addition to a large residential population, and many of the commercial waste loads are rich in recoverable materials.

The SWD estimates that about 6 to 8 percent of the current 270,000 tons-per-year of waste processed through the Bow Lake station could practicably be separated and diverted for recycling and reuse. The Bow Lake station serves a large industrial, commercial and warehouse area of the county in addition to a large residential population, and many of the commercial waste loads are rich in recoverable materials.

Materials targeted for recovery include clean wood, cardboard, film plastics, carpet and textiles, and scrap metals. Most of this material will arrive in mixed commercial loads and require some sorting. Trucks carrying rich loads will be directed to the sorting end of the tipping and receiving floor, well away from the MSW tipping area. The SWD expects to use a rubber-tired or rubber-tracked material handler and one or more skid steers to sort the materials in these loads, but may begin by using a simpler piece of equipment such as a conventional backhoe tractor. Hand sorting will not be used. Occasionally, one of the two large front-end loaders from the MSW area may be used in the recycling processing area, but generally, the processing and sorting operation will be kept separate from the MSW operations to minimize contamination of recovered materials. The processing area is in no way intended to be a “dirty MRF” –- a facility that sorts the entire MSW waste stream to extract recyclable materials.

Once the material has been sorted, it will be pushed to bunkers and held prior to baling, or, in the case of the carpet, wood and heavy gauge scrap metal, loaded into roll-off boxes. During the baling operation, the cardboard, film plastics, textiles and possibly light gauge scrap metal will be pushed from the holding bunkers onto an in-floor conveyor that will deliver the material to the heavy-duty two-ram baler. Baled material will be stored in a separate holding area or directly loaded into trailers or containers at one of two loading dock stalls. Material collected in roll-off boxes will leave through the main exit door of the receiving floor.

None of the SWD’s eight stations currently include this sorting and diversion capability, so the SWD expects that there will be some operational experimentation and learning involved when the new station comes on line. The primary motivation to introduce diversion to the transfer station obviously is to meet new policy requirements as well as avoid the costs of landfill disposal.

The SWD owns and operates its own landfill where King County MSW is currently disposed. Once the new Bow Lake transfer building is completed and operational in 2012, the facility will be adaptable for waste export to remote disposal at sites other than the county’s landfill.

Organics

While the existing station has no capability to separately receive and transfer organics, the new facility has a separate area set aside specifically to handle this waste stream. This area (see Figure 5) is located at the south end of the transfer building and is part of an area designated as the South Processing Area.

The 32,670-square-foot South Processing Area includes a covered top-load chute with four customer unloading stalls for organics and an adjacent covered area for the receiving and chipping of woody waste. The county is also looking into the feasibility of receiving and directly loading out non-residential food waste through the top-load chute.

The 32,670-square-foot South Processing Area includes a covered top-load chute with four customer unloading stalls for organics and an adjacent covered area for the receiving and chipping of woody waste. The county is also looking into the feasibility of receiving and directly loading out non-residential food waste through the top-load chute.

The South Processing Area also includes provisions for at-grade self-haul customer drop-off for recyclables either in roll-off boxes or inside a recycling building. Materials received here would include appliances, tires, automotive products (batteries, oil, oil filters and coolant), scrap metal, clean scrap wood, e-waste, compact fluorescent bulbs and tubes and propane tanks.

Other Features

The main floor area of the transfer building will include a 50,000-square-foot, 230-foot-wide clear span, flat-floor tipping and receiving floor with separate tipping areas for self-haul residential and commercial customers; two 120-ton-per-hour preload waste compactors; a two-acre trailer/container parking yard; an on-site fueling station; staff support facilities including a break room, offices, locker and shower rooms, and a meeting/training room. Other innovative features include:

Tire wash for commercial customers exiting the tipping area to eliminate tracking of waste onto the site roads

A truck washout station

A dust extraction and collection system

A dust and odor misting system

A methane barrier and venting system for all indoor spaces

A vehicle exhaust gas monitoring system

Photovoltaic power generation

Rainwater harvesting for use in the non-potable wash-down water system

An external structural column system to increase usable interior area and reduce the accumulation of dirt within the building

Variable fluorescent lighting system for operations areas combined with extensive natural light

Heat recovery and reduced energy consumption mechanical systems

A goal of achieving the U.S. Green Building Council’s LEED Gold certification

Conclusion

It’s telling that the area devoted to material diversion and recycling at the new Bow Lake station is about equal to the area devoted to MSW transfer. This design represents a major step in the evolution of transfer stations. In SAIC’s work evaluating existing transfer station operations and planning and designing new stations, many solid waste customers around the country have expressed a growing interest in how they can practically divert recoverable materials that, for various reasons, cannot practically be diverted at the generation source, or where incentives cannot be implemented for source separation and diversion. In most instances, retrofitting existing transfer stations that were not sized or configured for this type of recovery operation is not practical, but inclusion of this capability may be worth considering when a new station is planned.

Karl Hufnagel is a senior project manager with SAIC Energy, Environment & Infrastructure, LLC, a wholly owned subsidiary of SAIC. He is managing the design, permitting, environmental review and construction management support services for the Bow Lake project and can be contacted at 206-695-4509 or [email protected].

You May Also Like