NUMIX Materials Metals Recycling Technology Aims to Promote Circular Economy

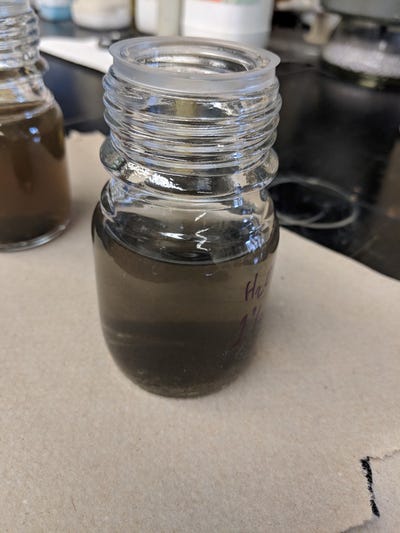

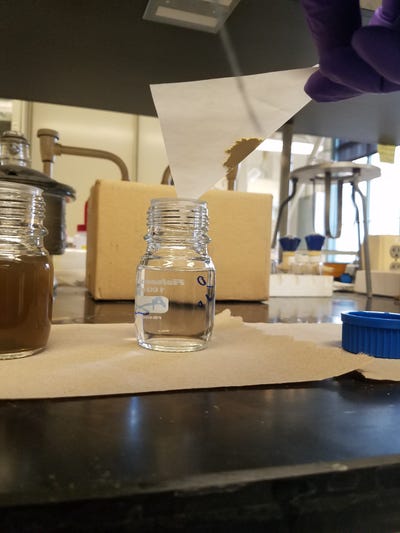

Startup company NUMiX Materials has developed a technology it hopes will provide what NUMiX CEO Katie Kollhoff calls a missing link in the metals supply chain to promote a circular economy. The company makes engineered sorbents to remove dissolved metals in water, allowing water to be filtered and the metals to be recovered.

There are similar processes to deal with these materials, but Kolloff says what differentiates NUMiX’s technology is the concentration that the sponge-like sorbent can take up.

“If you put in one pound of our product you can take out one pound of metal contaminant for downstream recycling. Other processes may require up to about 1,000 pounds of treatment material to one pound of materials retrieved,” she says.

Wastewater treatment plants leverage a similar purification process to the one that requires more treatment materials in order to comply with discharge limits of metal contaminants. But existing methods generally result in high sludge, which must be solidified and landfilled, and does not allow for recovery of metals.

Further, most water purification processes are done in large mix tanks and require additional specialized equipment to recover metals, but NUMiX’s process would eliminate the need for some of that equipment.

“So if you are an electroplater, which is one group we target, you will have a water treatment train, which includes a step for metal removal. We created a way to just swap materials they normally put into that metal removal mix tank without having to install more equipment,” says Kolloff.

Processors would also be able to use a fraction of treatment materials, translating to less residual waste for disposal, and they could recover what residuals do remain, which contain a higher concentration of desirable metals than would be recovered if using a high waste-generating treatment method.

Kollhoff believes the technology has potential to work for the mining industry, including mining-affected water, and in jewelry making.

“At some point in time each of those segments dissolves metals in water. For example, all three segments would have dissolved silver in the stream. Being able to solidify and recover that silver could cut down on overall waste expenses while creating value from that stream,” she says.

The new technology could also have value to the copper mining industry, while turning a potential problem into an asset, she believes. Copper often coexists in the ground with cobalt, which can remain in final products and is considered harmful and or a contaminant in copper products. But they could recover it as a byproduct that is needed for lithium-ion batteries.

Kollhoff sort of fell into her special niche rather than having planned her course from the start.

She was working as a safety engineer at Northwestern University, helping research groups develop hazardous waste management processes and techniques. One group had a process that dissolved metals in water streams and needed a filter to solidify those trace contaminants.

“I could not find anything. I learned the next best option was to put contaminated water into 20-liter containers and ship them to hazardous waste treatment facilities – at about $3,500 per container. One of my co-founders had been designing large-scale wastewater treatment equipment, so we put our heads together and decided we could have the most meaningful impact by building on hazardous wastewater and chemical processes,” says Kollhoff.

They came up with a treatment process to enable recovery of dissolved metals, a reduction in hazardous waste generation, and reduction in total material throughput.

Kollhoff met her cofounding team when doing the earlier work at Northwestern and developed the business idea there. She gained initial funding, then was selected to participate in the Chain Reaction program at Argonne Lab, for innovators focused on energy and science technologies. There she got support as she worked on making bigger batches of sorbent and worked to optimize the metal recovery process.

NUMiX’s innovation earned it the first-ever U.S. Bank Cleantech Inclusion Award to support female and minority entrepreneurs working to benefit the environment and drive economic development.

“Most investors only look at opportunities referred to them by their network. Females and persons of color may have limited networks. So, we are trying to shine a light on compelling inspirational female or minority entrepreneurs. Also, we realize by highlighting them they can be role models for others deciding to pursue opportunities in STEM (Science, Technology, Engineering, and Mathematics) disciplines,” says Erik Birkerts, Clean Energy Trust CEO. Clean Energy Trust is funded by the philanthropic arm of U.S. Bank.

Birkerts said the plan is to grow the program and to attract additional forward-thinking corporations to provide funding.

As the inaugural award recipient, NUMiX Materials received a $25,000 grant and 12 months of business mentorship and programming.

To date, Kollhoff and her partners have done a few demos with potential customers (electroplaters) while looking for partners interested in waste reduction measures and others with a need for domestic-sourced metals as raw materials.

About the Author

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)