The New Landscape: China’s Contamination Ban & The Future of Profitability in Recyclables

How haulers & generators can significantly reduce contamination in recycling to make collection & processing profitable again.

May 25, 2018

Sponsored Content

What used to be a reliable revenue stream for North American haulers with China paying big bucks for U.S. recyclables regardless of contamination, is now a cost as China’s unwillingness to take recyclables is forcing recyclers to stockpile material or send contaminated recyclables directly to landfills instead. With this new landscape, what has been a $5 billion annual business (CNN Money) is in significant danger and has our industry at an important decision point: How can we regain and strengthen recycling revenue streams while supporting the growing movement of reducing waste being sent to landfills?

The Old Way: Manual "Lid Flipping"

Prior to the ban, the emphasis on contamination in the U.S. wasn’t a pressing priority and conducting limited “spot checks” at various dumpsters, once or twice a year, proved to be a sufficient method of oversight. But with new, strict requirements putting limits on contamination and increasing the need for more frequent and accurate monitoring, “lid flipping” as an oversight strategy simply won’t work - the fact is, China won’t be reverting back anytime soon, if at all. “Lid flipping” is now too inefficient and costly and can only provide limited, outdated information that can’t realistically be implemented for full scale oversight of our recycling stream.

We cannot continue to act and behave as if business as usual will offer a solution to today's issues. – National Recycling Coalition

But, the ban isn’t necessarily a bad thing - in fact, leaders across our industry believe this is a significant moment forcing us to finally have an overdue conversation about our recycling practices and start implementing new, viable solutions that provide a path to profitability for haulers that increases diversion from landfills.

[The China ban] gives us the platform that we need [to] have the conversation that we frankly probably should have been having 10 years ago, – Don Slager, CEO, Republic Services (via WasteDive)

A Simple Solution: Cameras Inside Every Dumpster

In-Container cameras are the next logical step in contamination identification and they’re already being used in thousands of dumpsters across North America. These cameras eliminate the need for “lid flipping” by automatically identifying (and alerting for) contamination and showing haulers exactly what’s inside every dumpster, every day through web-based software. Remote access to dumpster images, taken multiple times per day, combined with contamination identification capability gives haulers an unprecedented level of oversight into the contents of their customers’ containers

Instead of conducting expensive, labor-intensive, infrequent and time-consuming content audits, I can remotely monitor our customer’s containers 365 days a year with Compology’s hardware and web-based software to help them reduce contamination and increase diversion. – Joe Mats, District Manager, Universal Waste Systems

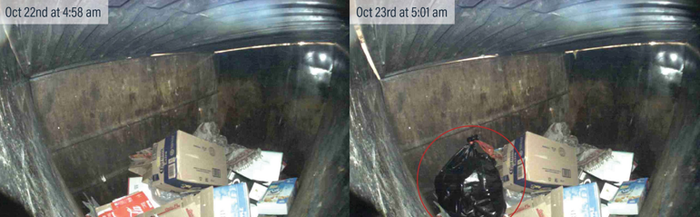

Compology camera images providing a first-hand look at the contents of any container, making contamination identification possible on a large and consistent scale.

In the end, cleaner streams mean a re-emergence of revenue for haulers that disappeared nearly overnight. In-container cameras provide an unmatched level of quality and high-frequency container images, along with automatic contamination alert capability, that put haulers on the track to profitability by allowing them to 1) effectively educate generators and enforce compliance and 2) create cleaner streams with informed routing.

Effective Education & Enforcement

Identify Poor Performers: Automatic outreach to generators letting them know what specifically to change about their behavior for full compliance using images as a teaching tool.

Enforce Fines: While many cities already have legal structures for fines, contamination images provide indisputable proof of contamination and let haulers fine those generators that are not compliant without dispute.

Track Sustainability Metrics: Haulers can actually track and measure improvements in recycling and even share that data with generators for sustainability leaders to measure and report on zero waste and diversion goals.

Inform Public Policy: With more frequent, accurate contamination information haulers can work with policymakers to identify overarching contamination issues and the true costs of recycling operations to create policies & business models that are effective and profitable.

Cleaner Routes

Route Based on Dumpster Cleanliness: Being able to identify which dumpsters are contaminated before building routes lets haulers create routes that service only non-contaminated dumpsters, keeping their recycling stream clean.

Set Automatic Contamination Alerts: Haulers can even send automated contamination alerts to customers to remove contamination prior to service helping customers avoid potential fines and as a timely and useful educational tool.

Not only is this technology of high value for the recycling stream, but it’s also already being used for organics as well. For more information on in-container cameras and contamination identification, contact Compology and visit compology.com.

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)