How Lebanon, Tenn.’s Planned WTE Facility Will Work

Last week, PHG Energy (PHGE) and the city of Lebanon, Tenn., announced a partnership to launch a waste-to-energy facility early next year at the city’s wastewater treatment plant. The new facility will use the downdraft gasification technology, which will cleanly convert up to 64 tons per day of blended waste wood, scrap tires and sewer sludge into a fuel gas that will generate up to 300kW of electricity.

The project will be the largest known downdraft gasification plant in the U.S., according to Chris Koczaja, vice president of engineering and implementation for Nashville-based PHGE. “The patented core design elements of our technology are a departure from traditional downdraft gasifier designs allowing it to overcome the air distribution challenges that have traditionally limited the size of downdraft gasifiers,” Koczaja says. “In research and practice, we have not found a downdraft gasifier as large in operation.”

The downdraft gasification process relies on heating biomass in an oxygen-starved environment, like other forms of gasification, but downdraft has a significant difference.

“The difference with downdraft is that both the biomass and air enter from the top of the gasifier with gravity assisting to move the material down through the system,” says Koczaja. “The gas exits the bottom of the gasifier after being forced to pass through the hottest zone of the machine resulting in a cleaner gas than other forms of gasification.”

By creating an oxygen-starved environment, gasifying the waste materials results in a cleaner conversion by limiting the formation of pollutants over what would be generated by incinerating the same material, according to Koczaja. By using biogenic carbon sources or materials that would be destined for landfills, the biomass contributes to a reduction in carbon emissions making it a green or cleaner process.

Lebanon city officials learned of the possibility of this type of waste-to-energy plant by attending the commissioning ceremony of PHGE’s Covington, Tenn., plant in October 2013.

After the ceremony, “we invited PHGE to Lebanon to discuss possibilities of putting together a plan for us to divert waste from landfills,” says Lebanon Mayor Philip Craighead. “They did a feasibility study on a 64-ton facility for the City of Lebanon. The results of that study were very positive.”

The city has been awarded a $3.5 million federal bond subsidy for this project, of which the city will receive a 70 percent reimbursement of all interest payments related to this bond, according to Craighead.

After the site visit, the city contacted PHGE to see if it would be a candidate for this kind of plant. PHGE then conducted a feasibility study and identified operational savings at the wastewater treatment plant as well as potential cost savings in processing local scrap tires and industrial waste.

Since one of the feedstocks will be the wastewater sludge, the facility’s location next to the city’s wastewater treatment plant will eliminate transportation costs as well as landfill tipping fees, plus it is located on city-owned land.

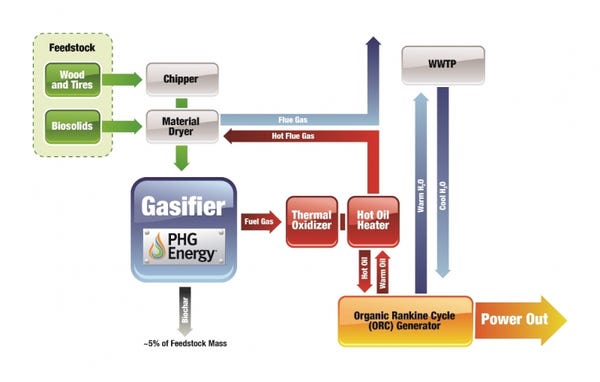

Lebanon Process Flow Diagram

PHGE and the city of Lebanon are hoping to break ground on the facility in April, with a projected completion date of April or May 2016.

“The plant for Lebanon is a good model for an industrial manufacturing facility and/or municipality that is daily facing the costs and volumes associated with the removal of waste streams and would like to offset electricity costs,” Koczaja. “One of our primary objectives in analysis is finding the financial foundation that gives the customer economic benefits along with the environmental benefits.”

According to Koczaja, those projected benefits include:

$250,000 per year in electricity and operational savings by changing the way the city disposes of sewer sludge

Tipping fees derived from local industries who will contribute manufacturing wood waste to the process instead of transporting it to a landfill

Income from Wilson County (where Lebanon is located) for cleanly disposing of scrap tires through the gasification process

Keeping more than 8,000 tons of material out of landfills each year

Preventing the release of more than 2,500 tons of carbon dioxide into the atmosphere each year

Mayor Philip Craighead City of Lebanon

Craighead adds that the city’s projections show positive cashflow for the plan beginning in its first month of operation.

“We expect the state [of Tennessee] in coming months to require a substantial mandate of diversion from local landfills,” he says. “This project will enable Lebanon to get out in front of these future mandates. Our long range goals are to institute a larger recycling program, which would hopefully include 100 percent diversion of our local garbage from landfills.”

Along with those benefits, the City of Lebanon will face a learning curve and challenges in operating the new facility.

So far, Mayor Craighead says the project is proceeding smoothly with the total support of city council and state environmental oversight.

“We are eager to get this project operational�—to not only save our taxpayers dollars—but to support our local environment,” he says.

About the Author

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)