Glass Recycling: Myth Vs. Fact

Few pros in the recycling industry will say it’s impossible to recycle glass. But many questions remain about this practice, from how glass impacts contamination of the rest of the stream to whether there’s money to be made in working with glass.

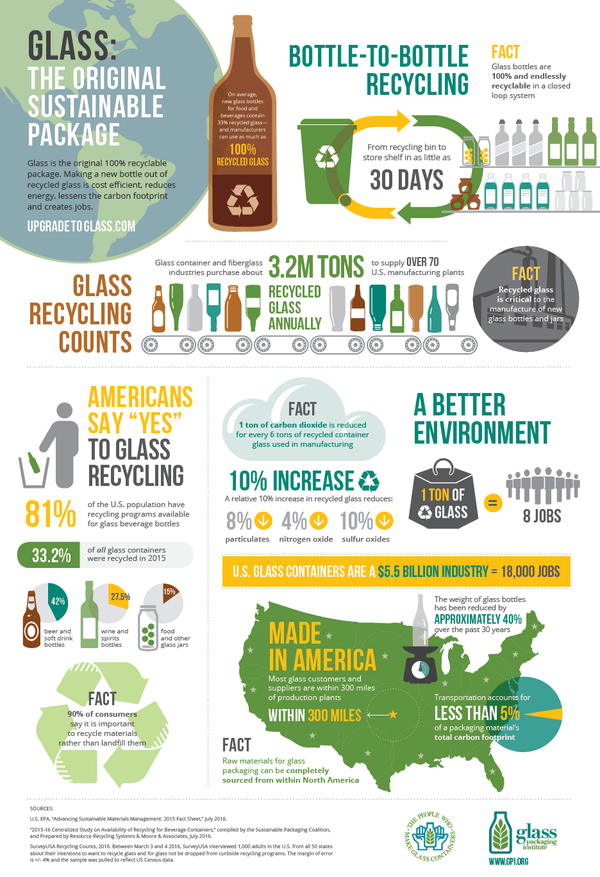

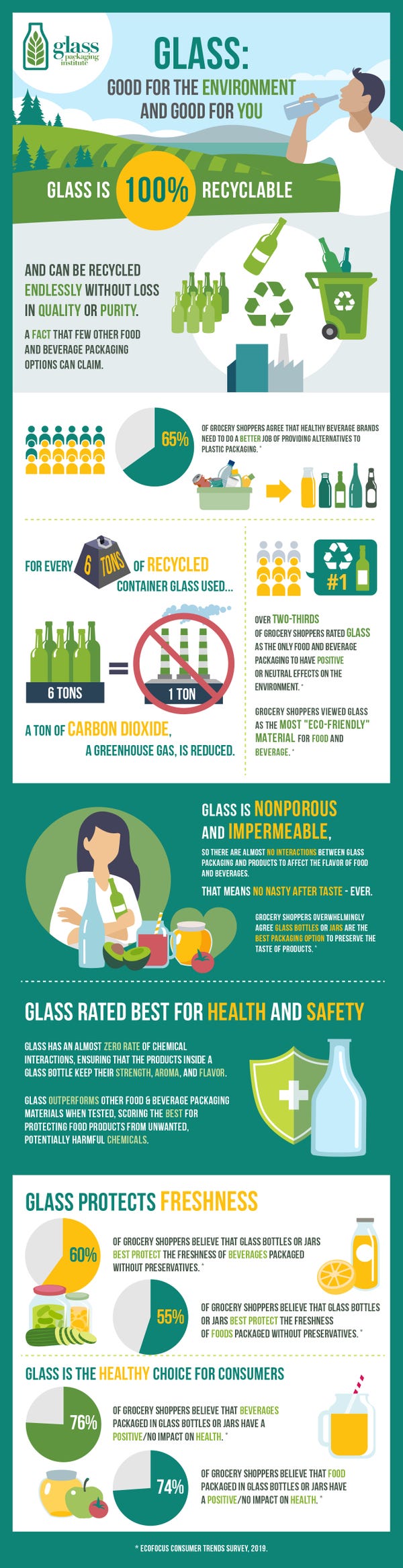

With input from Strategic Materials, the largest glass recycler in North America, and data from the Glass Packaging Institute (GPI), this article calls out common myths and clarifies facts regarding glass recycling.

MYTH: Broken glass cannot be accepted.

Municipalities that offer glass recycling accept broken glass. Even when it’s unbroken in the bin, glass breaks when it goes through the sortation process at material recovery facilities (MRFs), and secondary processors are actually required to break and crush glass to make products. Strategic Materials often encourages glass to be broken because it can then pack more material by weight into its trucks.

MYTH: Mixed-color glass cannot be accepted.

MRFs and secondary processors accept mixed-color glass. Some markets, such as glass container markets, do require color-sorted material, but there are other outlets in which color sorting is not needed. Fiberglass insulation is color-blind, as are filler products, which include any product that can replace sand, such as carpet backing, paint fillers and filtration media.

When mixed-color glass needs to be separated for the end market, processors and some MRFs have optical sorters to color-sort the material.

MYTH: Glass must be washed and cleaned.

Labels and organics that cling to glass do not present a significant problem because they are removed during secondary processors’ operations. Although secondary processors and glass recyclers prefer that glass be washed and cleaned because it helps with odor and general processing, it is not a requirement.

Strategic Materials says it has few problems with labels because it crushes glass via multiple passes, removing labels in the process.

As for organics, while this type of waste is messy, the crushing and separation process removes most organic material, and then the glass is dried to remove any remaining liquids or moisture.

MYTH: It’s impossible to prevent glass from contaminating other recyclables.

Single-stream collection methods create contamination for every material in the recycling bin, not just glass. But proper layout, sequencing and processing at MRFs maximizes the value of all material streams.

Glass should be removed at the beginning of the process, which enables better recovery of other materials in the stream further down the MRF sorting lines. In addition, removing glass at the beginning of the sortation process helps reduce wear and tear on equipment and requires no additional labor.

Strategic Materials, in a survey of 85% of its U.S. MRF suppliers, found that none reported rejecting any paper or plastic loads, and none reported downgrades due to glass contamination.

Contamination is not a major barrier if a MRF has thoroughly sorted before sending glass to processors. Otherwise, processors have to separate and pay to have non-glass materials landfilled, notes Laura Hennemann, vice president of marketing and communications for Strategic Materials.

MYTH: Glass cannot be recycled due to China’s National Sword policy.

Glass has never been exported to China, and glass recyclers have no plans to do so. It’s recycled domestically. Some operations have removed glass from their recycling programs since China’s National Sword policy went into effect, but Hennemann says that’s because now that processors have fewer outlets for paper and plastics, they are seeking to get more value from those materials. In doing so, they have opted not to accept glass, and instead to collect more paper and plastics.

In summary, says Hennemann, glass has been removed from recycling programs not because it’s unrecyclable or without value but because other materials are being prioritized.

MYTH: Recycling glass provides no financial payoff.

Using large quantities of glass significantly decreases the amount of energy required to run furnaces, which can actually result in overall cost savings for glass container manufacturers.

The value of glass can be maximized with proper processes and equipment.

It’s important to note that the value of glass depends on its level of contamination when it arrives at the secondary processor’s facility: the more contamination it contains, the lower its value.

A primary driver for contamination is single-stream collection.

Another issue impacting contamination levels is that investments in glass cleanup systems have not kept pace with MRF needs, and then there is inadequate maintenance at the MRF, Hennemann says.

Weather events come into play as well. Snow and ice are considered contamination to secondary processors.

MYTH: There are no end markets for glass.

Some end markets include container, fiberglass insulation, and highway bead. Demand exceeds supply in many areas. Glass container producers and fiberglass insulation manufacturers are setting higher recycled-content objectives, and they need more recycled glass to accomplish this.

MYTH: Glass should be removed due to expense and difficulties in processing it.

Removing glass could have negative impacts on MRFs and little impact on its value to municipalities, according to Hennemann.

She says that major waste management companies nationally and a major equipment manufacturer agree that if 20% of the material is removed from a MRF, the processing per ton cost decreases minimally, although, they only looked at removing 20% of the entire mix to include about 15% to 20% glass.

Potential MRF equipment maintenance savings from removing glass are $3 to $5 a ton, according to Hennemann, which would not preclude it from being a profitable undertaking.

MYTH: Recycling glass creates a higher safety concern for MRFs than other materials.

The inference that handling glass at the MRF level is excessively unsafe is not supported by studies conducted by the Solid Waste Association of North America, the Institute of Scrap Recycling Industries, or the U.S. Bureau of Labor Statistics, Hennemann says.

Her company, Strategic Materials, handles nearly 3 million tons of glass a year, and in 2018 the company had a total recordable incident rate of 2.2 incidents across the company. That compares favorably to the MRF 2017 rate of 9.8, which accounts for the handling of all materials processed at MRFs.

New or retrofitted MRF designs, which remove glass from the front end of the system, do not require any labor on the glass line, thus reducing the chance for safety risks.

About the Author

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)