May Fire Report: Lithium-ion Battery Fires Are Everywhere

In this month’s column, I highlight recent fire data as well as provide highlights from my education session on fire safety at WasteExpo 2023.

In this month’s column, I highlight recent fire data as well as provide highlights from my education session on fire safety at WasteExpo 2023.

April 2023 Fire Data

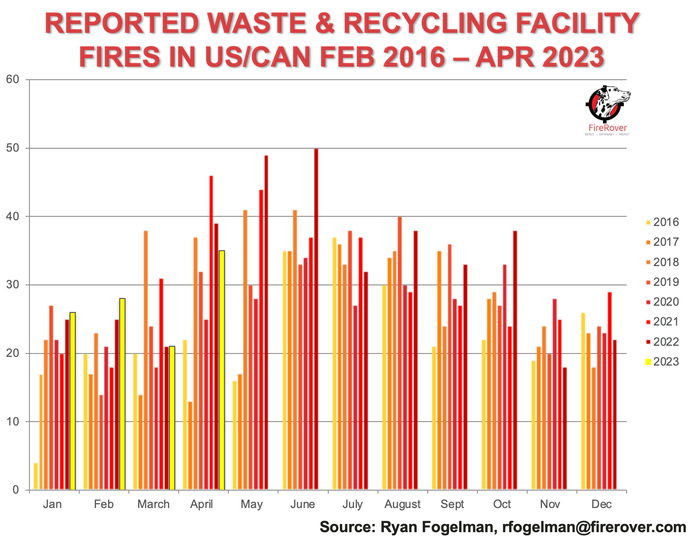

As we come off a record year for reported fires at our waste and recycling facilities, highlighted in my recently released annual report, "Waste & Recycling Facility Fires Annual Report," the good news is that April’s reported fires were down from their seven-year trend. But unfortunately, the first four months of this year were the same as our first four months of last year, which ended up as the worst year we have had for reported facility fires in the U.S. and Canada.

Unique from last month, scrap metal recycling fires overtook waste, paper and plastic fire incidents. Of the 35 reported fire incidents that occurred in April, 16 occurred at scrap metal recycling facilities, 12 occurred in waste, paper and plastic facilities, three occurred at organics facilities, two occurred at hazardous material recycling facilities and one each occurred at construction and demolition and electronics recycling facilities. At Fire Rover, we responded to more than 250 hot spots and/or fire incidents at our clients’ facilities.

Lithium-ion Battery Fires Are Everywhere: An Overview of the Problem and Solutions

For WasteExpo 2023, I was asked to assemble a panel to discuss the trends and best practices for fire prevention, detection and response. I was fortunate to present with a fantastic panel with unique perspectives from some of the best operators in the U.S. In this month’s article, I highlight the panelists’ actions or advice that can help the rest of the industry with its fire planning.

Logan Miller, Regional Recycling Manager, Rumpke Waste & Recycling

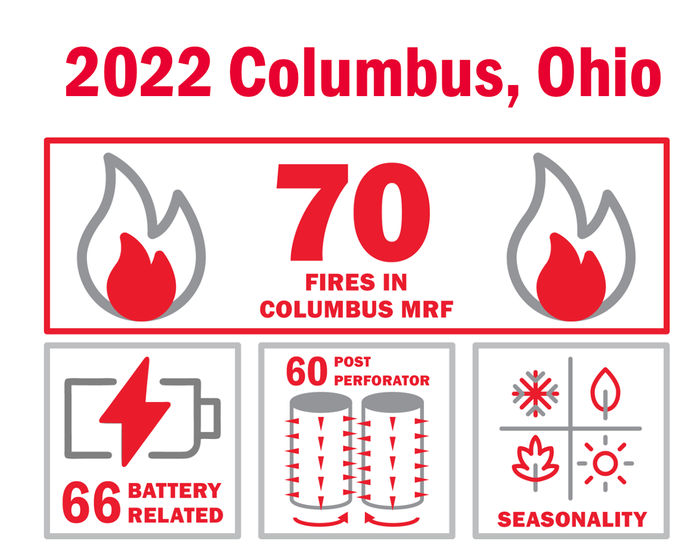

Miller presented information on Rumpke’s newest materials recovery facility (MRF), a $90 million facility being built in my backyard of Columbus, Ohio. Before diving into the design, he shared with attendees that Rumpke’s MRFs were inundated by lithium-ion battery fires in 2022.

Specifically, the company had 70 fires in its Columbus MRF in 2022, mostly due to the perforator needed to ensure the plastics were prepped for recycling. Of those 70 fires, 66 were reported to be caused by lithium-ion batteries. As you can imagine, I was floored by these numbers. If every MRF in the U.S. saw the same number of fires, my 2,600-plus fire incidents in the U.S. and Canada would be dwarfed by the reality of 70,000 actual fires. This number is just in the estimated 1,000 MRFs, not the transfer stations, scrap metal facilities and other waste and recycling facilities that equate to about 10,000 facilities. I have always known my estimate of 2,600 fires was conservative, but this disparity would be mind-blowing.

The good news for Rumpke is that these learnings have been integrated into the new MRF’s designs, and the perforator has been engineered out of the new equipment.

Dan Kurtz, Executive Director – Recycling, Waste Connections

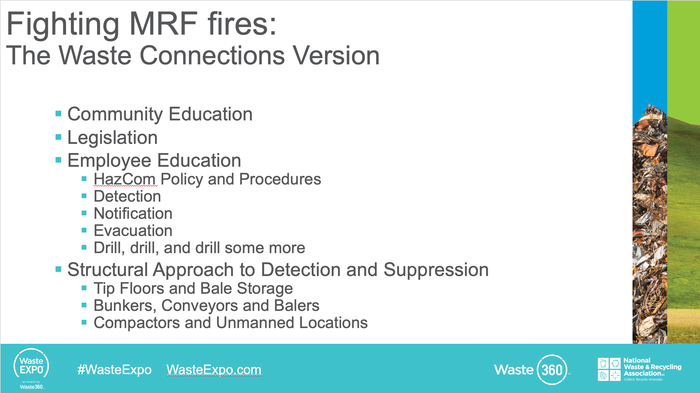

Kurtz’s presentation focused on how Waste Connections uses a multilateral approach to fight its fire hazards.

Education and legislation are always key to helping Waste Connections’ customers understand the hazards and their responsibility for what they are throwing into their recycling bins and to helping drive the rules that need to be changed from a regulatory perspective. Waste Connections also does an amazing job protecting its facilities based on the unique fire hazards and requirements of each of the areas of its MRFs, but in my opinion, the most significant part of what the conpany does is educate its employees on safety when dealing with fire hazards.

This approach makes me most proud of how the waste and recycling industry has changed since 2015. The fact is most of the fires in this industry are caught when they are in their incipient stage, and educating, preparing and drilling your employees is key to safe and positive outcomes.

James “Andy” Lynch, Fire Protection Engineer, Founder and CEO, Fire Solutions Group

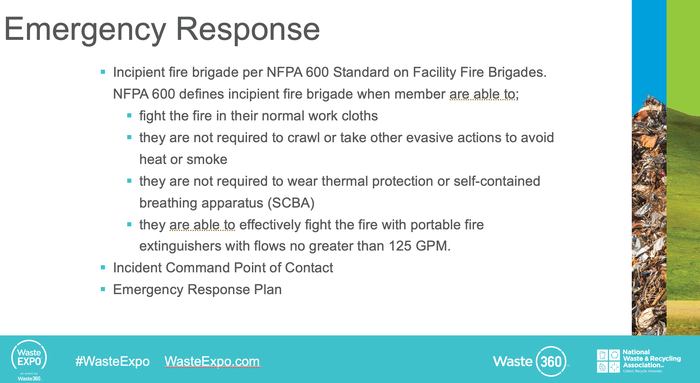

That leads me to one of the things that Lynch shared with the group on the specifics of having a safe and effective “incipient fire brigade.” For those who don’t know Lynch, he is a fire protection engineer whom I have been working with since 2017. Together, we have developed several custom early fire detection solutions, both through our Fire Rover boxed unit and our continuous flow solutions. Many of these have received both formal and informal variances to operate as a facility's primary fire protection. Even with all the best technology out there, your employees are on the frontlines, preventing and reacting to fire incidents at their facilities.

Lynch shared the below outline of the National Fire Protection Association 600 Standard on Facility Fire Brigades and how it defines an “incipient fire brigade.” This definition is important because there is a fine line between responding to an incipient fire and evacuation only, so proper training and employee education is paramount.

An incipient fire brigade is not a trained fire brigade, and it is true that some companies take this responsibility to an extreme level that can lead to hazardous results. Most companies take the position that employees are not required to fight fire incidents, and if they have any questions or concerns, they should evacuate.

The issue comes into play in areas where the fire professionals are not trained to fight these types of fires or are made up of 100% volunteers. In these cases, the line between fire professionals and incipient fire brigades can blur. My recommendation in these cases is for the company to formalize its fire brigade program and get employees the proper training and equipment needed to fight these fires. Without this training, or some sort of early detection and suppression technologies, these companies remain at a high risk of a catastrophic loss if an event gets out of control.

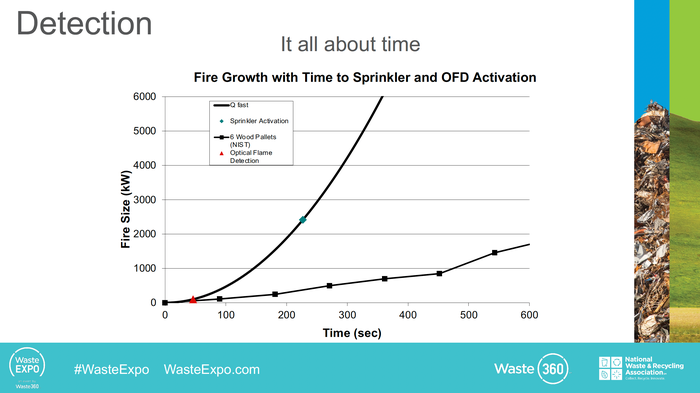

Another slide that Lynch shared during our session showed the reaction time between when a sprinkler system in industrial occupancies will react versus early detection technology, like our Fire Rover. The fact is the earlier you detect a fire, the easier it is to have a better outcome. As an industry leader, Michael Hughes from Casella Waste Systems often says, “Fires grow in size and cost every second they are not detected and suppressed.”

Conclusion

The waste and recycling industry is in a tough position. We are asked to be the stewards of our future of green initiatives, but at the same time, we are faced with hazards in epidemic numbers every day. (See the cover photo of an e-bike battery that went into thermal runaway on my client’s tip floor in New York City). I am proud of the waste and recycling industry for seeing this trend in 2018 and developing new technologies, training employees, educating the public, driving the proper legislation and more in an effort to help the public come through on their promise to reduce, reuse and recycle.

If you would like a copy of our presentation from WasteExpo 2023, you can find it here.

Ryan Fogelman, JD/MBA, is vice president of strategic partnerships for Fire Rover. He is focused on bringing innovative safety solutions to market, and two of his solutions have won the distinguished Edison Innovation Award for Industrial Safety and Consumer Products. He has been compiling and publishing the “Reported Waste & Recycling Facility Fires In The US/CAN” since February 2016 and the “Waste & Recycling Facility Fires Annual Report.” Fogelman regularly speaks on the topic of the scope of fire problems facing the waste and recycling industries, early detection solutions, proper fire planning and early-stage fire risk mitigation. Additionally, Fogelman is on the National Fire Protection Association’s Technical Committee for Hazard Materials. (Connect with Ryan on LinkedIn at https://www.linkedin.com/in/ryanjayfogelman or email at [email protected])

About the Author

You May Also Like