Key Takeaways from Day Three at WasteExpo 2019

Here's a look at the panel sessions and key takeaways from day three of WasteExpo.

WasteExpo 2019 sessions for day three focused on contamination, single stream versus dual stream recycling and maximizing organic waste diversion. Here is a look at some of the key highlights from some of the most notable panel sessions of the day.

In a session called “Single Stream vs. Dual Stream,” Willie Puz of the Solid Waste Authority of Palm Beach, Fla.; Anne Germain of the National Waste & Recycling Association; and Louie Pellegrini of the Peninsula Sanitary Service shared their take on which of the two collection systems is best and why. Moderated by Rachel Oster of Diversion Strategies, this presentation also shed light on special considerations to get the cleanest stream beyond simply going with single or dual stream.

Marin County in California began segregating at the curb in the 1980s—even sorting what is still one of the most problematic materials—glass, recalled Pellegrini, who has served the region for decades. Then in the 1990s, single stream became the trend, where all materials were tossed in one bin, adding a convenience factor for residents and haulers.

Peninsula Sanitary Service collects and processes materials to prepare them for market. “The way we do it is with a split collection vehicle and split cart in a dual stream collection. Fiber is on one side, and bottles, cans and glass are on another side,” said Pellegrini.

He gets more commodity value than single stream tends to because materials come out cleaner.

“We have sent materials directly to paper mills. Glass breaks, but they are larger pieces and can be color sorted,” he said.

Pellegrini doesn’t get high value for glass. But the California regions he services have a bottle bill, “so we have to collect glass; it’s not going to go away in California,” he said.

His cost to implement a dual stream automated collection system is 21 cents per household.

Single stream collection yields at least 20 percent residuals while dual stream yields about 10 percent. Pointing out proponents of the latter system, the issue appears to be that with single stream, people toss more in the bin that doesn’t belong there.

However, challenged Germain, contamination is not just about the bin system. Key to participation for a successful program of any kind is to understand what has to be done for success.

“If you go to single stream and have robust education, would material become as clean as with dual stream?” asked Germain.

Among reasons she believes contamination is often high with this system is “wishcycling,” where people toss items in the bin not knowing if they can be recycled, hoping they can be.

Mandatory participation also leads to increased contamination—some if forced won’t make the effort, especially if they don’t understand why they should follow the rules.

Pay-as-you-throw, where people are charged less for recycling more and for throwing less in the trash, contributes too, she pointed out, commenting, “When people run out of room, they have used recycle bins as trashcans.”

Meanwhile, she said some communities running single stream programs with robust education have 8 to 12 percent contamination.

When dual stream is utilized, she said, automated systems with split vehicles (more than one compartment) are most efficient. Though haulers should be aware they will get less material and have higher costs.

Palm Beach County in Florida has done dual stream for 20 years, other than in the city of Lake Worth. But the city recently transitioned to dual stream.

Solid Waste Authority of Palm Beach County, which delivers the service, offered Lake Worth a 50/50 revenue share on commodities. At the time, the municipality was having to pay $85 per ton to have materials taken away.

Like Germain said of single stream, education with dual stream was key.

The authority developed news releases, and the city’s newsletter carried the same message about the pending change. Sandwich board street signs and billboard ads were also utilized. Stickers were put on each cart; ads went out in the community paper and the authority produced videos explaining how to recycle.

Residents originally objected to the change, but that didn’t last long, said Puz. Prior, the city had a 20 percent contamination rate, which has since dropped to 5 to 7 percent.

“It’s been a great partnership and success story of a city going from single to dual stream,” said Puz.

Still, what works best depends on what a community wants and what it’s prepared to do, according to some recycling experts.

Germain referred to a city in Japan that actually separates waste into 34 categories. It has an 81 percent recycling rate. They can’t do curbside recycling; instead, they operate a central facility.

“They seem happy with their process. But those who add more materials need to have a flexible system that can manage them,” she said.

In “Maximizing Organics Waste Reduction and Diversion,” Veronica Pardo of California Refuse Recycling Council (CRRC), Eric Herbert of Zero Waste Energy, Kimberly Scheibly of Marin Recycling & Resource Recovery and Terry Keene of Keene Environmental Consulting discussed, among topics, what an ambitious bill will mean for California’s waste professionals and up-and-coming technologies to maximize diversion.

California’s SB 1383 passed in 2016 but is in the rulemaking period. It’s got the state’s solid waste industry talking about demands and big changes it’s already having to prepare for.

The bill calls for a 50 percent reduction in organic waste from 2014 levels by 2020 and 75 percent by 2025. That equates to 20 million less tons of organics disposed than today, said Pardo.

“An earlier bill defined organic waste as food waste and yard waste. But SB 1383 is a different animal because now anything that creates methane is defined as organic waste. Now, we are looking at textiles, paper and lumber, so it’s a huge change,” she said.

The expectation is that these materials will be tracked and sampled. As the bill reads now, jurisdictions also would be required to have standardized cart colors to distinguish waste types. As currently proposed, the bill also would require haulers to identify generators that are contaminating and to have a system to go back to them to resolve.

The bill imposes an obligation on jurisdictions to procure compost and renewable natural gas. There has been an attempt to expand the definition to include renewable electricity, Pardo told event attendees.

CRRC members are concerned about whether the industry can handle the volume of materials driven by the policy.

“Only a quarter of facilities in California can accept food waste now. Only 4 million tons of capacity are available. California needs an additional 20 million tons capacity by 2025,” said Pardo, who anticipates a steep learning curve as the industry tries to adapt.

“We know how to do green waste, but with food, you deal with odors and [other management issues],” she said.

CalRecycle has tentative plans to hold its next workshop in mid-June, and the regulatory language should be presented then. Then, there will be a comment period.

“We continue to have conversations around siting, permitting and funding streams for not just traditional food waste but paper, pulping and other materials. Meanwhile, the regulations are expected to begin in 2022. So, we are not that far away,” said Pardo.

Herbert talked about several technologies to divert organics. These are not low-cost solutions, but increasingly, they are perceived as valuable, especially by entities looking to offset their carbon.

"Customers say, 'we want this,' or waste companies say, 'I can differentiate myself by diverting organics from mixed waste,'' said Herbert.

He described a few technologies, including advanced mixed waste processing to segregate materials and prepare them for an automated process. A system running 100 tons an hour would require only 16 human sorters.

Herbert also touched on advanced in-vessel composting. This process, when combined with another system, receives material in one end, which is turned and moved to the opposite end. Then, it’s postprocessed with screens. “You can take paper and organics and have a finished compost in 21 days, which is the best we’ve seen,” said Herbert.

Another technology involves making an engineered fuel, which can be burned in industrial environments like cement kilns. In California, these plants must reduce emissions now or buy carbon credits, so this is a good application, he said.

Hebert provided diversion figures for each of these technologies: 15 to 25 percent for advanced mixed waste systems, 25 to 45 percent for compost (when compost and anaerobic digestion are combined it’s higher) and 20 to 40 percent for engineered fuel (or solid recovered fuel).

Moving forward, he projects, “We will be seeing a lot of automation involving robotics, optics and screening, which are meeting market demand well. They require less human labor, get higher throughputs, are cost effective and yield high-quality products.”

Marin Recycling owns and operates a number of facilities, including a recycling center that processes 250,000 tons annually. It has made a concentrated effort to mitigate contamination.

“We do a lot of education and outreach. We learn from best practices—tools that work. And we ask what didn’t work to not repeat mistakes,” said Scheibly.

It’s important to know your customer base, she told event attendees. “Learn their behaviors because this will affect composition of feedstock.”

Marin Recycling has done focus groups, talking to property owners and multifamily and single-family residents. And the company did a waste characterization study to see what was thrown away. A third of it was organics.

What’s especially key to making organics collections work, she said, is to have an outreach coordinator and a lot of communication.

“Some of our outreach staff have worked in restaurants and are aware of backend functions and can give advice like how to lay out their kitchens,” she said.

She left attendees with this final message: “It’s important to engage in training and retraining and collect and inspect and repeat. If you do that, you will have successful programs. If you continue the process routinely, your result is really clean feedstock.”

Keene Environmental Consulting recently did an organics diversion feasibility study for Philadelphia, the sixth largest municipality in the country, which disposes 1.3 million tons a year.

“We found that about a third of residential waste is organics and about 34 percent of the commercial stream is organics. So, we estimate there are about 130,000 tons that may be available to do something with,” said Keene.

But Philadelphia has limited capacity to handle organics. So, the question became how could they identify process capacity as well as collection options?

Among Keene’s recommendations were to expand an existing compost operation at a large municipal park to enable it to process up to 9,000 tons a year, more than doubling capacity. Keene recommended a second compost site and to increase capacity at processing sites at a local prison and the Philadelphia Water Department.

And he suggested tracking large anaerobic digestion projects as there is one under development for renewable natural gas that could take materials. Encouraging community organics programs was a part of the mix, too.

“The city only has about five programs now so grass roots community opportunities have not taken hold yet, and they are important for the system to work,” said Keene. He added that public and private partnerships may be the answer to increasing organics management.

“Philadelphia is in its infancy in looking at zero waste. It’s a long process and there is no one silver bullet.”

NOTHING WASTED! is a new WasteExpo offering—the solid waste management industry version of TED Talks where aspiring thought leaders share in an open forum some visionary ideas. One of the first forums, “NOTHING WASTED! Pioneers & Visionaries,” featured Monica Wilson of GAIA U.S. Office, Eric Randall of Bryson Recycling, JD Lindeberg of Resource Recycling Systems and Lisa von Sturmer of Growing City.

Wilson shared stories of cities around the world that have embraced zero waste, where the priority is identifying what is left in the stream to make best use of it. One example was Tacloban in the Philippines, where the government started working with Mother Earth Foundation along their journey to zero waste.

By emphasizing source separation, improving collections, setting up decentralized composting and conducting community education and outreach, the city went from 30 percent collections to 100 percent in six months.

GAIA is pushing to get brands to be more accountable for their products, especially single-use plastics.

“Here in the U.S., we’ve been told by brands and the plastic and packaging industries to collect their products, but we are learning a lot of plastics are ending up in Indonesia. We know they are coming from the U.S. as we have traced materials,” said Wilson. From there, she had a proposition for recyclers.

"The recycling community is in a great position to help get the message out [that we have too much plastics]. They can make clear to brands what will work and what will not work; they can say, 'we need less single-use plastic, so we can get our job done,'" she said.

Randall flew in from Northern Ireland to tell of how Bryson Recycling is working to play a role in transforming the industry there.

“In the early 2000s, we saw European directives requiring us to collect at the curbside. We did door-to-door collections of recyclables at 8,000 households to figure out how much materials were produced from different socioeconomic homes. And we looked into what best to invest in,” he said.

The company, which is buying a plastics processing plant, also invested in Kerbside Boxes, a curbside system of three stackable containers on wheels. The top box holds paper and fringe items like batteries and foils; the middle box holds plastic bottles, cans and cartons; and the bottom is for glass and cardboard.

The material is dumped into a multicompartment truck. Each compartment opens separately so material can flow out to the tip floor, which opens to a pyramid shape.

The company is making money on commodities, which Randall attributes to this system overhaul. “We have the ability to recycle more because we collect so many materials in one pass.”

Though collection costs more, materials recovery facility costs are nearly nonexistent, he said.

“We save landfill space, save cost to landfill and get valuable products. And the public likes that we are not shipping [materials] into the unknown or depending on export markets,” said Randall.

Von Sturmer told a captive group why she left her job as a TV editor to start hauling organics in Vancouver, British Columbia, Canada..

“I went on a trip to an island that was no waste and came home thinking about all the compostable tons going into the trash at work. I decided I wanted to do corporate organics recycling. It could be an opportunity to do something that people wanted to do but not do themselves,” she said.

There were plenty of challenges along the way: a fallout with her business partner; having to figure out how to handle organics in a less than ideal setup—she hauled them around in a minivan—but she was strapped for cash and couldn’t get a bank loan.

A turning point came when she went on a Shark Tank-type show and her idea was chosen as second-best pitch in nine years.

“The phone started ringing off the hook. But now, I had a problem where everyone wants service and I wasn’t prepared to handle it,” she said.

The main challenge was in trying to keep drivers. The culture wasn’t working for them. They didn’t want office parties; they just wanted to get in the truck and go.

Von Sturmer created a driver incentive bonus program, which was another turning point. The main program feature is automated monthly reports to benchmark performance. Now, her drivers are coming to her and collaborating because they want to improve.

This reporting system also had a huge impact on Growing City’s bottom line due to improvements, like a 45 percent decrease in service times.

The company now offers a menu of services, from waste audits to waste room optimization and other support services. And von Sturmer just got her first municipal request for proposal.

She sees more opportunity down the road as a result of regulatory changes.

“It’s a great time to be a small, independent company. We can do things faster and be more nimble than big guys. So, these challenges are a chance to add revenue.”

Lindebergm talked about what he called a “highly predictable” crisis—China shutting the door on U.S. recyclables.

“China had requirements years ago, and when recyclers weren’t meeting them, the result was Green Fence and then National Sword. But it was good for us because it challenged us to deal with that we can’t ship large amounts to China that are just barely not waste,” he said.

“We get to focus on creating high-quality products and markets. Markets are there for plastic glass and other materials but quality has to be there."

Lindebergm ended with insight on how to make recycling work: Invest in education to teach people how to recycle right and reduce contamination. And know that in the trenches, face-to-face engagement is more effective than social media. Understand that customer’s trust is critical, and if you lose that, you lose the market.

Ultimately, he said, “In the end, this is an opportunity for all of us to participate in something concrete that allows us to deal with systemic problems and improve the planet.”

Day three of WasteExpo 2019 also included the first-ever Waste360 Business Growth Forum hosted by Comerica and designed for small and midsized environmental services companies looking for business and financial strategies that go beyond day-to-day operations. During the forum, attendees learned how to grow organically, dive into mergers and acquisitions, financing, success stories and more.

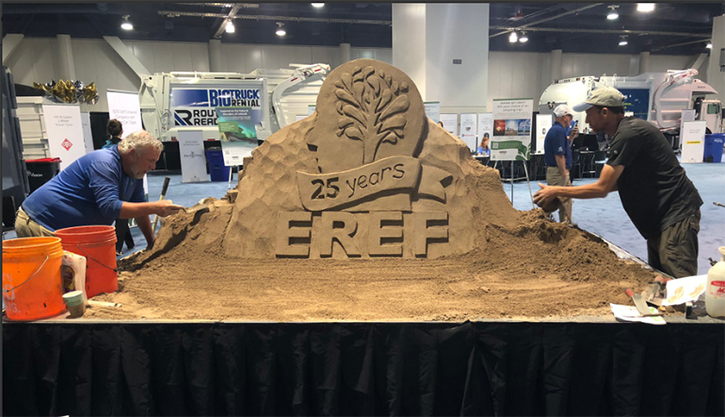

Day three also featured the Environmental Research & Education Foundation's 25th Charitable Auction. At the auction, items for bid included golf outings with some of the top executives from the solid waste industry's publicly-traded firms, as well as trucks and equipment from the industry's top manufacturers.

The Waste360 Healthcare Waste Conference also kicked off. At the conference, attendees checked out the latest and greatest medical waste offerings and tuned into informative sessions led by leaders in the industry. The conference runs through Thursday.

About the Authors

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)