Analyzing Waste and Recycling Facility Fire Data

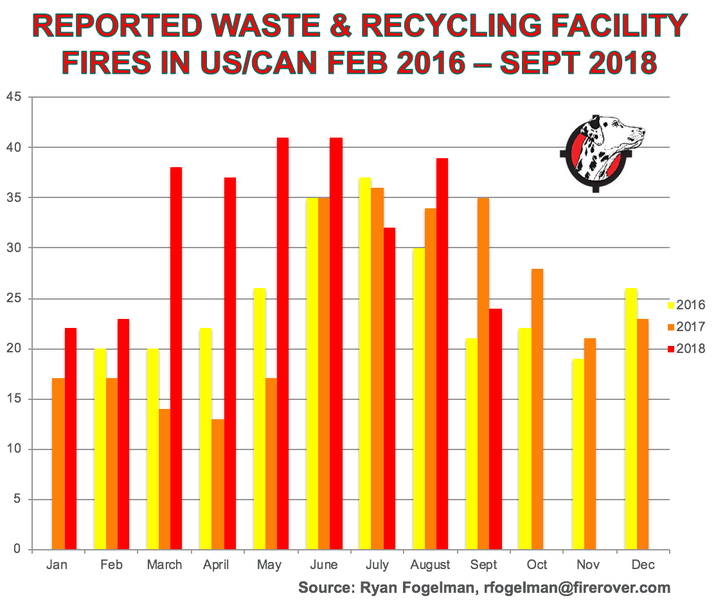

Waste and recycling facility fires starting to level off since spike in the first half of 2018.

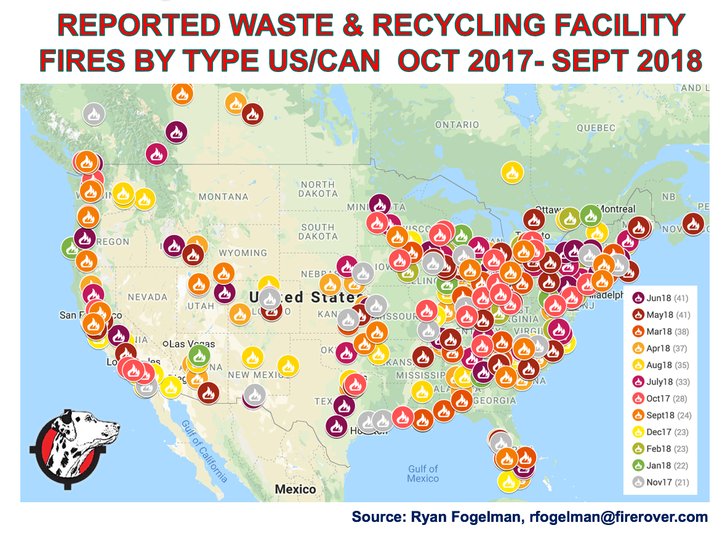

Over the past 12 months, the waste and recycling industry has experienced 366 reported fires in both the U.S. and Canada. Based on reasonable assumptions, we can extrapolate that 1,800-plus facility fires have occurred in the past 12 months, which based on the number of facilities reported by the Environmental Research & Education Foundation (EREF), is more than 40 percent of the industry.

There were also five deaths and 13 injuries reported during that time. Most of these injuries and deaths were suffered by the brave fire professionals called in to fight and contain these incidents.

Waste and recycling facility fires have started to level off over the past three months from their sharp increase in the first six months of the year, but total reported fire incidents are still up 36 percent for the year when compared to the same period in 2017. When looking at the rolling 12-month total, we are experiencing a 29 percent increase in reported fires year-over-year.

For September, we experienced 24 fires as compared with 35 in 2017 and 21 in 2016. That equates to a 31 percent lower number than September 2017 and a 14 percent higher number than September 2016.

These fires are not only occurring at our materials recovery facilities (MRFs) and transfer stations but also at our scrap metal, construction and demolition, paper, plastic, chemical and organics recycling operations. They are caused by a list of fire hazards, including, but not limited to, lithium-ion batteries, pressurized tanks/containers, fuels, fertilizers, propone tanks, aerosols and more.

Most fires are caught during their very early stages, but as one can imagine, the fires that are being reported by a news outlet have typically passed the incipient stages. Most of these incidents incurred significant damage and downtime and are required to be fought by local firefighting professionals.

Causes of these fires range from traditional material hazards, such as pressurized tanks, chemicals, hot work activities, hazmat smoking and newer hazards like lithium-ion batteries. No matter the cause or the risk, even the best operators are not able to completely eliminate their risk of fire. It is imperative that they develop and continuously revisit their fire plan. The proper defense consisting of training, operations, equipment and technology can mean the difference between getting a fire incident under control early versus the alternative of a complete shutdown.

I asked David DeVito, director of regional operations for ReEnergy, his best advice for protecting his operations from fire incidents, and he said:

Have an emergency contact list at local police and fire departments

Coordinate contingency planning walkthroughs with the local fire department

Offer training for employees

Fire separation and accessibility

Develop health, safety and environmental procedures and controls

Ensure local employees for quick response are on call for accurate and up-to-date information

Maintain a healthy combination of the right fire technology and equipment

Ryan Fogelman, JD/MBA, is vice president of strategic partnerships for Fire Rover. He is focused on bringing innovative safety solutions to market. He has been compiling and publishing the “The Reported Waste & Recycling Facility Fire In The US/CAN” since February 2016 and the “Waste & Recycling Facility Fire Annual Report.” Fogelman speaks regularly on the topic of the scope of fire problems facing the waste and recycling industries, detection solutions, proper fire planning and early-stage fire risk mitigation.

About the Author

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)