5 Ways To Manage Your Waste Container Inventory

This article is brought to you by Compology, a provider of container monitoring software for waste haulers.

Sponsored Content

Why Does Container Inventory Management Matter?

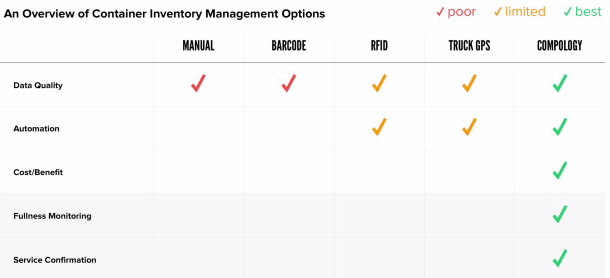

Traditionally, when haulers think about inventory management they’re mainly concerned with how many containers they have available to sell, which can often be determined by walking the storage yard. However, additional information such as knowing how many containers are deployed, their locations, and how long they’ve been there can prove to be extremely valuable when it comes to streamlining operations. To manage container inventory, haulers can implement a manual, barcode, RFID, truck-based GPS or container-based GPS tracking solution.

Having complete, accurate and up-to-date container count and location allows haulers to turn containers faster, reduce expenses through inventory control and ultimately, grow their bottom line. Container-based GPS stands out as the best-in-class option due to its unmatched container count and location accuracy. Compology's container-mounted sensor is not only equipped with GPS to meet inventory management needs, but also delivers the added benefits of fullness and motion tracking for a complete container monitoring solution.

Compology’s container-mounted sensor provides best-in-class inventory management through GPS as well as fullness and motion tracking for a complete container monitoring solution.

Manual Tracking

The original, low tech, container inventory management system: an employee visits storage yards to count the quantity of each size container and logs their notes into back office systems to align with what’s on-site with customers. That information is then recorded in a spreadsheet or an inventory tracking software.

Automation: None. This process is labor intensive and leaves the possibility for human error at multiple points of manual data entry.

Data Quality: Front-load containers change location infrequently, so they can be relatively straightforward to track manually. Roll-off containers can move multiple times daily, increasing the importance of having up-to-date information about where a container is located. Accurate container information is difficult to achieve through a manual data collection process because by the time information is entered, it has already become outdated. Haulers might know where a container was a few days ago, but they can never truly have complete, updated location information.

Cost: There’s no equipment to purchase, but it requires employee time. Additionally, incomplete, outdated information can result in haulers unnecessarily turning away work or buying too many containers.

Durability: In our industry, where safety and health are top priorities, we all need to be aware of how much we ask of our teams.

The Verdict

Manual inventory management is simple and affordable to implement, but it’s also labor intensive and has a highchance of human error. It’s a logical and solid place to start, but as a business grows manual tracking becomes unmanageable.

Barcode Tracking

Yes, we're talking about the same black and white coded labels that we see on everyday products at the checkout line. Barcodes are placed on waste containers and are scanned by drivers when a container is picked up or delivered. The container information is recorded and periodically uploaded to an inventory management software.

Automation: Barcodes cut back on manual data entry, but the process remains labor intensive as someone must still physically scan each individual barcode from close range. Because of this, a simple mistake can cause a forgotten or faulty scan.

Data Quality: Accuracy is still an issue for barcodes, although they require slightly less data entry than the manual approach. Barcodes can give you a good sense of your container inventory for front-loads, but fail to provide up-to-date data on containers that move often.

Cost: Barcode stickers and scanners can be affordable and are expected to become less expensive in the future.Still, barcodes require a time commitment from employees and incomplete, outdated information can result in haulers turning away work unnecessarily or buying too many containers. (Our research has shown barcodes can be approximately $.15 per sticker and scanners can range from $40-$500 each.)

Durability: Barcodes work accurately on most materials (from fruit to steel!). However, they run into reliability issues with scanners and dirty, torn, weathered or blocked codes.

The Verdict

Barcode inventory management costs more than manual tracking, but is able to lighten the manual data entry process. Unfortunately, it remains a labor intensive process vulnerable to human error. If a hauler is looking to use technology for inventory management, there are automated, more reliable solutions available.

RFID Tracking

Radio Frequency-Identification (RFID) tags can track and identify a waste container in a process that is very similar to barcode scanning and have become common in residential waste collection. Waste containers are scanned by drivers, trucks or fixed scanners when a container is picked up, delivered or moved by. The container information, which can include much more detail than barcodes such as serial numbers or addresses, is recorded and periodically uploaded to an inventory management software.

Automation: RFID scanners can read over a longer range which enables the scanning of multiple containers at the same time. Scanners are installed at yards to track containers coming and going, or placed on trucks to track pickups and deliveries automatically.

Data Quality: If a storage yard or disposal facility is equipped with an RFID scanner, it can provide the correct count of containers entering or leaving. However, once a container leaves the storage yard, it’s location can’t be known unless a driver manually verifies or enters the delivery address. Integrating truck based RFID container tracking with truck-based GPS tracking can eliminate the need for any manual data entry. We’ll talk more about that later.

Cost: RFID tags are more expensive than barcodes, but remain reasonable in price. Outfitting trucks and/or facilities with scanners, however, can become a significant investment while still leaving openings for error. (We’ve seen that RFID tags can range from $.10-$20 per tag depending on the capabilities and quality. Handheld scanners can range from $1,500-$4,000 per scanner, while fixed scanners can range from $1,000-$20,000 per scanner.)

Durability: RFID tags are considered to be more durable than barcodes because of their hard plastic shells. Scanners have come a long way in terms of reliability, but are still prone to signal interference from buildings, trees and even the containers themselves.

The Verdict

RFID systems have consistently demonstrated their value in residential and some commercial waste applications, but the challenge of matching a container to a service location remains an issue for its wide scale adoption on roll-off. Ultimately, integrating with truck-based GPS is neccessary to get real value from RFID in any waste inventory management application.

Truck-Based GPS Tracking

An in-cab Global Positioning System (GPS) tracker pairs the coordinates of a collection vehicle with work order information to automatically associate a container with a customer. No container specific information is stored unless the system is paired with a RFID or barcode tracking system.

Automation: GPS tracking allows for automatic, continuous truck tracking. However, there is still a manual step toverify the pickup and dropoff of containers. Truck tracking is often combined with barcodes or RFID to help reduce human error in inventory management.

Data Accuracy: Today, GPS data is as reliable and precise as it gets. However, when it comes to container inventory management, truck-based GPS won’t get haulers complete container data. Only the last location of the truck is provided when the container is delivered, so there either has to be manual documentation of the container location or this process must be integrated with barcode or RFID systems.

Cost: GPS truck tracking services commonly have an upfront purchase and a recurring subscription on a per truck basis and act as a relatively low cost option for haulers. Again, to capture container data, there is typically an additional cost of installing a barcode or RFID system too. (In the market, purchase price for GPS trackers can range from $40-$300 each, while service agreements can range from $15-$45 per month per tracker.)

Durability: Durability is not an area of concern as the GPS tracker is usually mounted in the cab of a truck.

The Verdict

If a hauler is focused on truck performance, truck-based GPS is effective. However, when it comes to container inventory management, it can’t be relied on to provide accurate, up-to-date container locations without manual verification or integration with another system.

Container-Based GPS Tracking

When mounted to the container, GPS tracking follows a container’s every move and automatically pairs location information with customer accounts or work orders. This is most often used on open top roll-off containers and compactors and can be applied to front-load containers as well,

Automation: This is the only fully automated container inventory management solution that allows for continuous tracking without human intervention.

Data Accuracy: Fully automated GPS container tracking provides count, locations and time at location of every container with pinpoint accuracy. It does so while also identifying details such as the serial number of each unique container.

Cost: At first, container-based GPS trackers may appear to be a costly option because each container requires it’s own tracker. However, the value of having a solution that provides complete, up-to-date information, while also eliminating the labor intensive burden on employees, is the cost/benefit which needs to be weighed. (Today, Compology is the only container-based GPS tracking system built specifically for the waste industry. There is no upfront purchase and you can get started for as low as $7 per container per month.)

Durability: There are various GPS container tracking products available, but not all are built to withstand the severe conditions of the waste industry.

(Related: Compology’s container-based GPS sensors are built specifically for waste)

The Verdict

Container based GPS tracking fully automates the container inventory management process and allow for complete, up-to-date container counts and locations. With container-based GPS tracking, haulers can remove responsibility from their teams and trust the accuracy of the data. While the initial cost of implementation may be higher than other options, the return on investment is quickly apparent through higher quality data and the removal of manual data collection, freeing up employee time.

Compology’s Container-Based GPS Solution

Any technology being used has limited value if haulers can’t have confidence in their container location data. While a variety of the methods discussed deliver a complete container count, they leave more to be desired when it comes to automation and location accuracy. Container-based GPS tracking provides complete, automatic and up-to-date container counts and location as well as the ability to view updates remotely from a computer, tablet or smartphone, at any time.

Compology sensor securely mounted to a roll-off container.

When Compology set out to provide a complete container monitoring solution, the decision to equip our sensors with GPS to address inventory management was an easy one. To provide a best-in-class offering, we needed to deliver accurate, up-to-date container locations, and that’s exactly what GPS allows us to do. We also addressed any reliability and durability needs by building our sensor with reliability as the focal point. Our Compology sensor goes even further than a basic GPS tracking solution, offering haulers the option to not only remotely monitor container fullness in order to anticipate container service needs, but also the ability for motion tracking to help with service verification.

To learn more about Compology’s approach to container monitoring or to schedule a demo, please send us a note and make sure to subscribe to our blog.

About the Author

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)