Ins and Outs of Negotiating Energy Conversion Projects

Industry experts provide their views on what makes a sound energy conversion project contract.

Negotiating contracts for energy conversion projects involving processes like pyrolysis or anaerobic digestion can be involved. There are multiple considerations over the scope of what is typically a 15- to 20-year agreement, and changes can occur over time that impact outcomes and bottom lines.

So, when writing up terms, waste operations must meticulously think through what details need to be considered, including circumstances that can be anticipated and conditions that may not be predictable, in order to avoid costly surprises.

Waste360 spoke with an industry attorney, an environmental engineer and a waste management agency that has invested in several energy conversion projects in order to get insiders’ views on what makes a sound contract to set the stage for success. These waste pros touch on points from what’s negotiable to how to close loopholes that could benefit contractors at the client’s expense. They answer questions such as, if the client is outsourcing the service, what controls should they maintain? How do you negotiate feedstock performance guarantees? And what terms do you write into the contract as securities should the technology not meet expectations?

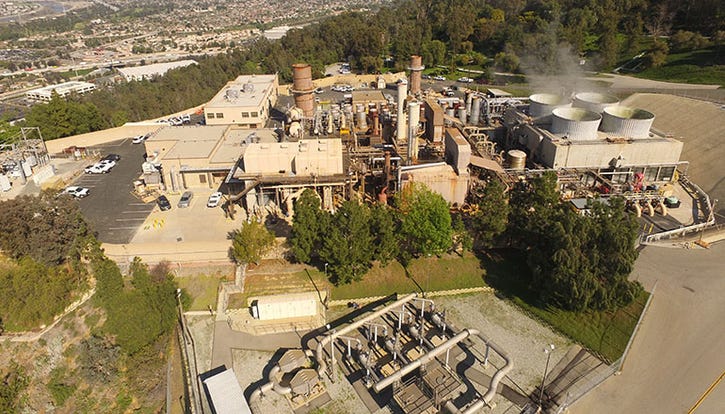

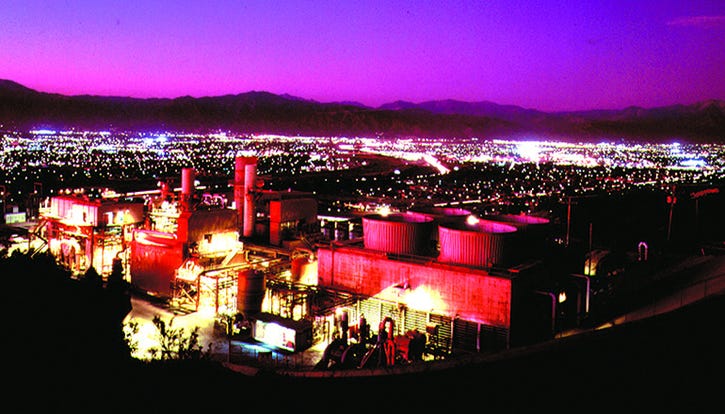

Sanitation Districts of Los Angeles County (LACSD) operates three gas-to-energy projects and has one under construction. The existing operations are at Puente Hills and Calabasas Landfills and at Joint Water Pollution Control Plant, a wastewater treatment facility.

LACSD’s strategy begins at the procurement stage.

“One path that we try to avoid for these projects is a design-bid-build process where we go out to public bid and the lowest bidder builds the plant. This is because our energy projects are highly customized and must reflect market conditions. Unlike design-build-bid, the request for proposal process gives us latitude to choose the best project for the agency. So, we pursue these design-build contracts and cut the bid out [when California law allows],” says Mark McDannel, manager of the energy recovery section for LACSD.

The next step is to define project scope, which involves finetuning the agreement and incorporating expectations.

“We have to ensure we get what we want without a change of orders with additional costs. And there are negotiations over how fast it can be done. We would write into the proposal package whether to charge liquidated damages should the project not launch by the date promised to recoup some of our loss [barring uncontrollable circumstances like bad weather],” says McDannel.

Attorney Constance Hornig advises her clients to write into the contract payment withholding rights to apply service fees to their costs when the facility is on unscheduled shutdown.

But among the most basic and main contract components is defining what will be in the current feedstock stream, what constitutes “contamination” and what must be recovered or produced (feedstock quality and quantity), she says.

“You need a waste composition that matches the technology. So, you must include preconditions of feedstock composition because this determines if the facility can accept or reject it, or if it has to meet its performance guarantees or is excused,” she says.

Hornig further suggests spelling out under what circumstances there may need to be a new composition study and who will pay for it.

There needs to be a clear delineation of whether the developer or customer bears other costs, such as for residue disposal, failing to meet operating guarantees, as well as major, anticipated, capital repairs and maintenance/upgrades.

And, according to Hornig, when customers are just contracting for the service, they must be able to inspect the facility and have prescribed records because there may be state reporting obligations.

If at some point the customer takes over operations, there’s plenty more to consider.

If the customer takes over operations due to a buyout or default, the contract must address their rights to assume contracts (power, fuel or compost sales agreements). Also, there must be clear, strong maintenance provisions that ensure the facility is optimally operable at the end of the original contract.

Prepare to avoid surprises that the contractor may come back with, especially when there could be extra, unanticipated work, says McDannel.

“For instance, in one of our projects, we defined the scope of work, but the developer said they had to dig around a pipe they did not know was there and wanted compensation. To avoid this, give them drawings. Or they may say they had to put in a deeper concrete foundation because of the soil type, so we have put in language that they can take soil samples,” he says.

As a general practice, LACSD’s engineering staff provides contractors with information and/or the opportunity to investigate themselves so they know what to expect with regard to the work ahead of them.

As far as what terms tend to be negotiable, Bruce Howie, vice president of HDR Inc., says they are typically those around energy output; hours in a year the technology must operate; how much residue is acceptable; expected recovery efficiency for post-processed metals; and minimum maintenance requirements and standards of care.

The biggest surprise Howie advises clients to prepare for is the possibility that technology does not meet expectations or fails to work altogether.

“Many times, we help clients avoid problems tied to technology’s performance by negotiating terms that limit a vendor’s or developer’s term and by expecting them to demonstrate, within that term, the technology can meet performance guarantees. If the technology or project isn’t able to demonstrate it can meet contractual obligations, liquidated damages can be levied. Or, in extreme cases, the contract can be terminated,” says Howie.

As a public agency, LACSD must keep its rates down to protect taxpayers’ money.

“There are challenges and surprises during construction, and contractors will find every loophole. So, the biggest thing we can do to keep costs down is to identify every detail before we start and have language in the contract addressing each,” explains McDannel.

About the Author

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)