WasteExpo 2018 News and Product Updates from Day Three

The third day of WasteExpo 2018 in Las Vegas brought a fresh round of news announcements.

Day three of WasteExpo 2018 brings more news from Mack Trucks, FleetMind Solutions, Fortistar, Thunder Creek Equipment, Freightliner Trucks, TOMRA, Trelleborg, Sierra International Machinery, Kraus Global, Eriez and Fairbanks Scales.

New Features on Mack LR Model Enhance Visibility, Driver Comfort

Mack Trucks has introduced new features on the Mack LR refuse model to help enhance safety, improve driver productivity and expand spec options for customers. Mack made the announcement during WasteExpo 2018, held April 24-26 in Las Vegas.

The new features include a sliding glass window on the passenger side of the vehicle, an exterior stainless steel sun visor and a Sears Seating C2 PLUS seat cushion. Mack also extended its 315 series tire coverage to include the Hendrickson HAULMAAX suspension.

“Mack continues to design and develop features on the Mack LR model that improve the working environment for the driver, help increase visibility in a refuse vehicle that already has superb visibility and provide customers with additional choices in how their vehicles can be set up,” said Curtis Dorwart, refuse product manager for Mack Trucks, in a statement. “The addition of these new options sets the bar for a best-in-class refuse vehicle that meets the needs of customers and drivers alike.”

The new sliding glass window greatly improves cab ventilation and access to the mirror during right-hand stand-up or sit-down operation. The window will be standard and available for order in Q2 2018.

The exterior stainless steel sun visor reduces glare and better deflects heat, improving driver comfort and safety. The stainless steel sun visor is now available for order.

The C2 PLUS seat cushion, available with Sears air suspension seats, provides even more comfort on the job. Mack’s new multi-position seat developed exclusively for the Mack LR by Sears Seating offers multiple positions for right-hand operation, allowing greater adjustability and comfort, whether seated or standing. The seat back and seat base are adjustable, allowing drivers to more comfortably operate the truck and joystick controls. The C2 PLUS seat cushion and multi-position seat will be standard and available for order in Q2 2018.

The ability to now spec Mack Granite, TerraPro and LR models with 315 series tires in all wheel positions offers a simplified ordering process for customers, while also enabling customers to more efficiently manage their tire programs. Expanded coverage of 315 series tires will be available for order in Q2 2018.

Designed specifically to meet the challenges of refuse customers who require enhanced maneuverability, increased productivity and improved visibility, the Mack LR model is offered in a 6x4 and 4x2 configuration. The LR is an excellent choice for customers in tight urban or open suburban applications. Several configurations are available, including left-hand drive, right-hand drive, dual-drive and left-hand drive with right-hand stand-up/sit-down drive.

Mack’s 11-liter MP7 diesel engine is standard in the LR model, delivering up to 355 horsepower and 1,260 foot-pound of torque. The LR is equipped with an Allison RDS five-speed or six-speed automatic transmission.

FleetMind Showcases Camera Systems for Complete Round-the-Truck Views at WasteExpo 2018

FleetMind Solutions, Inc., the award-winning technology leader for “smart truck” solutions, is highlighting its latest safety and monitoring camera systems at booth #3407 at WasteExpo 2018, held April 24-26 in Las Vegas.

“FleetMind provides multiple cameras for unprecedented insights into and all around your vehicles,” said Don Diego Padilla II, vice president of sales at FleetMind in a statement. “With our FleetLink Mobile DVR and Rear-View Safety products, you can easily take pictures, capture real-time video footage and ensure complete visibility around the truck. This lets you capture video of all internal and external activities from all angles, identify any driver-related safety issues for rapid remediation, capture evidence for accident and dispute resolution and eliminate blind spot areas.”

The FleetMind FleetLink mobile camera system includes:

FleetLink Mobile DVR is designed for tough refuse collection environments. It comes standard with WasteApp—a software specifically designed for residential or commercial waste management activities. It is used in conjunction with the back office and dispatch systems to record live digital video and all essential waste fleet management activities.

FleetLink Rear-view Safety System offers three options for rear view safety systems that can be customized to specific customer requirements. The MobileMule 5520 supports up to four cameras that all record simultaneously. The RVS Six-Channel DVR features a 9-inch display that can connect, view and record up to six cameras. The RVS-082507-NM backup camera system comes complete with a 7-inch LED Digital Panel color monitor and a 130-degree, one-third-inch SHARP CCD backup camera with 50-foot, infra-red night vision.

FleetMind Announces Purchase of Patent-Covering RFID and Other Forms of Electronic Tracking of Waste Containers

FleetMind Solutions, Inc., has purchased Patent No. 7,511,611 from longtime partner Casella Waste Systems, Inc. The patent essentially covers the tracking of a waste container with the use of Radio Frequency Identification (RFID), barcodes and other electronic means. FleetMind will be showcasing its FleetLink line of products that include RFID and visual tracking of individual waste containers at booth #3407 at WasteExpo 2018, held April 24-26 in Las Vegas.

“Smart truck systems designed to meet the needs of the waste management industry need to include RFID systems integration or other electronic tracking means for effective asset management,” said Martin Demers, vice president of FleetMind, in a statement. “In a nutshell, intelligent systems that integrate RFID technology can automatically identify items such as bins or containers that are being serviced. After having deployed products for more than a decade that have allowed our customers to improve their service levels and productivity, we now own the patent that covers the use of RFID technology in this context. Casella Waste is one of the most forward-thinking companies in this industry, and this patent further strengthens Fleetmind’s waste industry leadership position and ensures a great competitive advantage.”

The patent covers the use of an identification mechanism, such as an RFID tag or barcode, associated with a waste container. The identification mechanism contains an identifier that can be used to identify the waste container and be read by a vehicle with an identification reader. In addition, the location of the waste container can be determined using a GPS receiver. The waste container identifier and its corresponding location can then be stored in a computer for later transmission to a second computer, for example, by using a wireless communication link. The second can be used to associate the waste container identifier and the waste container’s position with a customer.

Fortistar Poised to Enter Construction on a Portfolio of Landfill Renewable Natural Gas Fuel Projects

Fortistar, LLC, a sustainability-focused private company helping to facilitate the transition to a zero-carbon economy, is entering construction shortly on a portfolio of new landfill renewable natural gas (RNG) projects for transportation fuel projects. Company executives will be attending the 2018 WasteExpo, held April 23-26 in Las Vegas, to discuss potential new projects with landfill owners, operators and project developers.

RNG, or biomethane, is American made from sustainable sources such as landfill gas and digester methane emissions. RNG is carbon neutral and chemically identical to geothermal natural gas, allowing it to be to be used as a transportation fuel in natural gas vehicles and trucks. Landfills are the major source of RNG.

The growth in natural gas fueling infrastructure spurred on by companies such as TruStar Energy, an affiliate of Fortistar, has dramatically improved the prospects for the development of a commercially viable RNG industry with distribution into the existing transportation fueling system.

“RNG offers a tremendous opportunity to sustainably expand America’s transportation fuel supply,” said Mark Comora, president of Fortistar, in a statement. “Our firm has operated in dozens of landfill gas-to energy-projects; TruStar Energy has constructed over 100 natural gas fueling stations. Fortistar is poised to close the loop in a coordinated manner and produce, distribute and supply RNG across the country. We are looking forward to speaking with industry and municipal representatives during the 2018 WasteExpo about developing our next portfolio of projects.”

Celebrating 25 years as a private company, and 20 years beyond that as an investment affiliate of a major international company, Fortistar has built, invested in and managed portfolios of successful, independent power and sustainable/clean energy generation projects in the United States and in Canada. Fortistar’s ability to forge strong relationships with investors, customers and local communities has been a hallmark of its demonstrated success.

Thunder Creek Redesigns Service and Lube Trailer with New Chassis, Expanded Storage and Fluid Options

Thunder Creek Equipment has redesigned its Service and Lube Trailer (SLT) to include a new chassis and front-end design, expanded storage in the front and rear utility boxes and a modular design that allows owners to add new features and components at any time after purchase.

The new SLT features a modular tank design that is capable of holding 440 gallons of fluid in up to eight tanks with combinations of 25, 55 and 110 gallons. This can include tanks for diesel fuel, oil delivery (engine or hydraulic), used oil reclamation, grease delivery, antifreeze, DEF and other fluids based on field maintenance needs.

“The Thunder Creek SLT provides a significantly lower total cost of ownership compared to full-sized lube trucks with similar capacities and functions,” said Luke Van Wyk, general manager of Thunder Creek Equipment, in a statement. “We give equipment managers the flexibility to customize their trailer with up to eight fluids, plus separate solutions for DEF and grease in the newly expanded front and rear compartments. Altogether, it is one of the most comprehensive field maintenance solutions available to heavy equipment fleet operations today. The ability for owners to easily field install many of these options after their purchase, such as the DEF system and the rear utility box, further allows the trailer to grow with their field service needs.”

The redesigned front-end allows for an additional 100-gallon DEF storage tank and Thunder Creek’s proprietary 2-in-1 closed DEF distribution system. This can either be included at the time of purchase or field installed at a later date. The new front enclosure is 23 percent larger than the previous model, and the rear utility box is 56 percent larger. These newly enlarged spaces give owners the opportunity to add toolboxes, workbenches, grease delivery systems and added oil/fluid capacity.

In addition to fluid delivery, the SLT is outfitted with either a combination generator/air compressor or an optional 3-in-1 welder/generator/air compressor. This helps power the pneumatic pumps for fluid delivery and other jobsite tools needed for field maintenance. An optional WorkSight Light Tower with powerful LED lights is also available for performing service work at night.

The SLT retains many of the design and performance features of the previous model, including 10-gauge steel tanks, interior LED lighting and the pneumatic pumping system with reels up to 75-feet long. The trailer can be purchased without the rear utility box and combination generator/air compressor for those who prefer to run the air off of their truck.

The redesigned front-end and chassis also helps make the trailer more maneuverable, and it features better access to working areas via hatch-style doors and ergonomically positioned components. The fenders are removable, and holes are pre-drilled into the frame to move the axle position and ensure proper weight distribution for owners who add features after the initial purchase.

The new SLT is manufactured in Pella, Iowa, and features Thunder Creek’s three-year tank warranty.

New Freightliner EconicSD Waste Collection Truck Unveiled at WasteExpo

Freightliner Trucks introduced the new Freightliner EconicSD waste collection truck at WasteExpo. The Freightliner EconicSD is a modern, low-entry cab-over-engine (COE) waste collection truck for the North American market that provides superior safety, uptime and productivity. Freightliner Trucks is featuring the Freightliner EconicSD in booth #2617 at WasteExpo.

“By working closely with our North American waste collection customers and analyzing how we could provide a solution that best benefits their businesses, we recognized the opportunity to adapt the Freightliner EconicSD for this market,” said Roger Nielsen, president and CEO for Daimler Trucks North America, in a statement. “Our customers continually seek to elevate the safety and performance of their waste collection vehicles, and the Freightliner EconicSD is the right solution for the distinct needs of this segment.”

The cab and chassis are designed and manufactured in Woerth, Germany—Daimler’s largest truck plant. More than 125 modifications were made to optimize the truck for North American operations. Final assembly of the cab and chassis will be completed in Gaffney, S.C., at the Freightliner Custom Chassis Corporation (FCCC) manufacturing facility.

Freightliner Trucks also partnered with Heil Environmental and McNeilus Truck & Manufacturing, two of the leading truck equipment manufacturers (TEMs) in the waste collection industry, to ensure the Freightliner EconicSD is ideal for the North American market.

“The cab-over-engine design for the North American waste collection market is a unique concept, so collaborating with Heil and McNeilus was critical to ensure a streamlined upfit process and efficiencies from the very beginning,” said Richard Howard, senior vice president of sales and marketing for Daimler Trucks North America, in a statement.

Powered by Detroit

Equipped with the new Detroit DD8 mid-range engine, the Freightliner EconicSD is built for productivity. With a rating of 350HP and 1050 foot-pound torque, the DD8 has best-in-class maintenance intervals that are up to three times longer than the competition. Ideal for the waste collection market, the DD8’s variable exhaust cam phasing optimizes exhaust temperatures during low-load operations for more efficient after treatment performance.

The DD8 also features Detroit Connect Virtual Technician remote diagnostic service for maximized uptime and productivity.

“The robust design and the technological achievements found with the DD8 engine make it well suited for the demands associated with waste collection,” said Jeff Allen, senior vice president of operations and specialty vehicles for Daimler Trucks North America, in a statement. “The Freightliner EconicSD and the DD8 make a durable and efficient combination.”

Unparalleled Safety

“Waste collection vehicles need to navigate tight turns, busy urban streets and suburban neighborhoods, so safety is a critical concern at all times,” said Allen in a statement.

The Freightliner EconicSD is engineered to enhance the safety of not only the driver and crew but also pedestrians and drivers of other vehicles. The truck’s panoramic windshield and low seating position provide outstanding visibility, while the mirror system offers an expanded field of vision for work areas and potential blind spots. The short wheelbase and aggressive wheel cut deliver superior maneuverability.

Further contributing to the Freightliner EconicSD’s safety is the Detroit Assurance suite of safety systems. The Freightliner EconicSD comes standard with active brake assist, adaptive cruise control and lane departure warning to mitigate potential collisions. Optional safety features include side guard assist and a built-in camera system with 360-degree views displayed on a flat screen dash monitor.

Designed for the Driver

The Freightliner EconicSD’s low entry means only one step is needed to enter the cab, with just one more step to the driver’s platform. The first step is only 19 inches, half the first-step height of many conventional waste collection trucks. A kneeling feature further reduces step-in height, while a lifting feature improves clearance over objects.

“Waste collection vehicle drivers and passengers are in and out of their trucks all day. The Freightliner EconicSD’s ergonomic design reduces fatigue and provides a more comfortable and productive work environment,” said Allen in a statement.

The spacious cab has an air-suspended driver’s seat, with additional single seating to accommodate up to three passengers in the high cab model. The Freightliner EconicSD comes standard with digitized instrument cluster that displays key information on an LCD screen on the dash and is operated by intuitive steering wheel controls.

“Inside and out, every aspect of the Freightliner EconicSD is designed with the customer in mind. We understand what impacts their bottom lines, and as their partners, we are driven to create solutions that contribute to their long-term success,” said Howard in a statement. “The Freightliner EconicSD is an exceptional solution that we are proud to bring to the North American waste collection market.”

The Freightliner EconicSD will be available to start ordering in summer 2018. Cab configurations for the EconicSD in 6x4, high cab and low cab, and rear and side loader configurations will be available.

The Freightliner EconicSD was adapted from the Mercedes-Benz Econic, a low-entry COE chassis that is popular with waste collection customers in Europe, Australia and Asia.

TOMRA Sorting Recycling to Feature Latest Equipment Innovations to Meet Tightening Purity Standards at WasteExpo

During WasteExpo 2018, representatives from TOMRA Sorting Recycling will its latest innovation designed to raise recycled product grade quality. Attendees visiting TOMRA booth #3601 will learn more about the new AUTOSORT LOD (Laser Object Detection), which uses laser technology to achieve unprecedented purity levels and helps recycling operations meet newly implemented China purity standards.

The new AUTOSORT LOD sorts based on the feed material’s spectral and spatial characteristics and detects impurities that near infrared technology (NIR) is incapable of identifying. AUTOSORT LOD cost efficiently sorts glass as well as plastic material and black plastic from paper, significantly boosting product quality. Foreground detection technology ensures the laser beam only identifies material above the belt, reducing background noise and giving operations the flexibility to use any type of belt feeder for the circuit.

“Our new, flexible LOD system features a modular design that quickly mounts onto an existing AUTOSORT platform or can be added as its own line, delivering significant cost benefits for recycling operations,” said Carlos Manchado Atienza, regional director Americas for TOMRA Sorting, Inc. in a statement. “Combined with our AUTOSORT near infrared technology, LOD gives customers an extremely efficient solution for upgrading product quality. TOMRA once again leads the industry in developing and adapting technology that meets the continually evolving specifications of the waste recycling industry.”

In addition to the new AUTOSORT LOD, TOMRA will highlight other technologies for waste, paper and plastics recycling, including X-TRACT. This cutting-edge X-ray sensor sorting system features TOMRA’s exclusive DUOLINE technology to give X-TRACT superior recognition of secondary resources, regardless of input material density. This high-speed X-ray processing technology delivers exceptional levels of resolution even with the most varied mix and smallest grain size.

“TOMRA offers a full range of sensor-based sorting equipment for the waste and recycling industry. With deep applications experience that spans more than 13,500 systems globally, we custom engineer our solutions to meet production needs, purity standards and budget constraints,” said Atienza in a statement. “We invite all WasteExpo delegates to booth #3601 to discuss their application challenges and how TOMRA can engineer a solution to meet those needs.”

Trelleborg to Display Full Range of Waste Industry Tire Solutions at WasteExpo 2018

Trelleborg Wheel Systems will display a full range of market-specific waste industry tire solutions at booth #137 at WasteExpo 2018.

“Trelleborg is a full-service supplier to the waste market, and we look forward to displaying our solutions at WasteExpo,” said Marc Margossian, marketing director for Trelleborg Wheel Systems in the U.S., in a statement. “We will be featuring our Brawler HPS Soft Ride Tires. Introduced at last year’s show, we now have hundreds of these tires in the field. The demand for Brawler has exceeded all expectations, the response from our customers has been overwhelmingly positive.”

The Brawler HPS Soft Ride solid tires offer operator comfort that is radically improved by more than 35 percent when compared to the standard solid tires used in waste applications. This figure was determined at an independent testing center in Treviglio, Italy, and confirmed through more than two years of field testing conducted at waste and recycling facilities around the world. The Brawler tires offer the life performance of a solid tire, with the ride comfort of a foam-filled pneumatic tire, providing customers with an ideal cost of ownership solution for the waste segment.

“The extensive testing conducted by Trelleborg before introducing the Brawler HPS Soft Ride to the market shows the company’s commitment to protecting people and assets,” said Margossian. “We took the time to respond to an industry need, to create a tire that our customers had asked for; one that provides more comfort for their drivers, which in turn leads to less downtime and more productivity.”

In addition to the Brawler HPS Soft Ride, Trelleborg supplies numerous products to the waste industry, including skid steer tires, rubber cutting edges and rubber tracks.

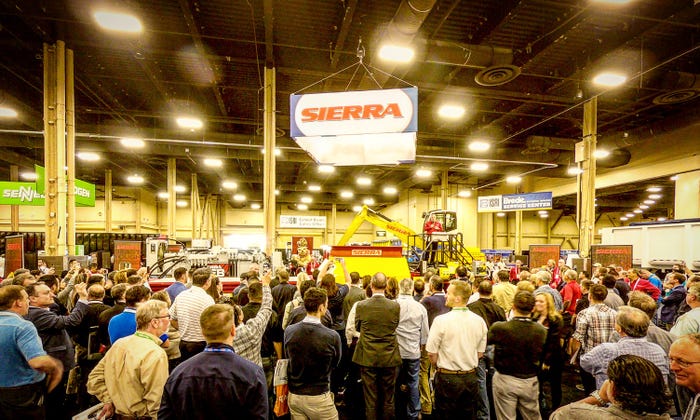

Sierra International Machinery Introduces REB4 Two-Ram Baler

The groundbreaking REB4 two-ram baler is the only two-ram that features Sierra’s patent-pending, dual-compression doors. The REB4 uses 55 tons of force per door to push the material below the cutting knife and into the charging chamber, increasing charging efficiency, eliminating roll-back and pre-densifying the material before the cycle even begins. This leads to a 20 to 40 percent increase in production.

“Our original two-rams are great machines, but we knew we could do better,” said John Sacco, president and owner of Sierra International Machinery, in a statement. “We didn’t set out to just make a faster machine by adding more horsepower or more pump speed; we set out to create a machine that actually solved the dilemmas and frustrations that recyclers face every day, such as roll-back, shear shock and hydraulic shock. By eliminating these frustrations, we’ve increased the speed, production and efficiency.”

The REB4 two-ram baler allows for greater input density in the charging chamber, which is dramatically different than traditional two-ram balers. When the doors are fully closed there is only a 6-inch gap that requires shearing, reducing the area to be cut by 90 percent, allowing for an overall reduction of shear and hydraulic shock and reducing stress on the blades and structure of the machine. This reduction in shearing also reduces energy cost, making the REB4 the most power and efficient two-ram in the world.

The dual-compression doors eliminate pinch points and allow for greater downward compression force on material without the worry of lid jamming. The unique design of the doors keeps the baler balanced without putting undue stress on the baler frame.

The REB4 two-ram baler is a gamechanger for two-ram machines. It was developed through years of experience in Sierra’s own recycling facility and was fully designed to eliminate the common frustrations prevalent within the recycling industry and increase production and efficiency.

Kraus Global Introduces Metered CNG Fill Post Systems

Kraus Global Ltd., a global leader of alternative fuel dispensing solutions and innovator of many recognized technological advances in the marketplace today, continues to shape the industry with the introduction of Metered CNG Fill Post Systems. Filling an equipment gap in the industry, this advanced intelligent post control system provides accurate metering from each vehicle hose. Embedded data acquisition architecture reports relevant historical and real-time data, providing station owners and fleet managers with a customizable summary of the health of the station and fleet.

Metering of fleet vehicle fills has always been a challenge, primarily due to cost and complexity. This challenge has been overcome through streamlining the necessary infrastructure and metering process using Kraus Global’s advanced MICON NEXTGEN 1.0 controller to extract and synthesize relevant data. System capabilities include enhanced fleet tracking, priority filling control, top-up routine, connection to fuel management systems and more. Existing time fill stations can be upgraded into the Kraus Metered CNG Fill Post System by retrofitting existing posts with a Kraus Fill Post Retrofit Kit and integrating the Kraus Control Panels to the site. This upgrade reuses existing compression, storage and filling infrastructure, making the total upgrade cost effective and easy to install.

“Beta testing of the Metered CNG Fill Post System is underway and going as planned,” said Ossama AbouZeid, president and CEO of Kraus Global Ltd., in a statement. “The system provides beneficial data and offers great advantage to those planning on installing time fill stations in the future. This new solution has caused tremendous customer excitement, especially given the option to retrofit existing time fill stations with this enhanced capability.”

AbouZeid stated Kraus Global is partnering with Ozinga Energy at the initial beta site. The Metered CNG Fill Post Solution will be on display at Ozinga Energy’s booth (#1617) at WasteExpo in Las Vegas. Sample data and equipment will be available for viewing, along with Kraus Global product specialists to share additional information and answer questions.

Eriez Announces New RevX-E Eddy Current Separator with Quick Change Belt System

The latest generation of the Eriez RevX-E product line combines the same high-performance separation of previous models with a variety of maintenance-friendly enhancements, including an innovative cantilever frame design that enables 10-minute belt changes. The company will present the RevX-E Eddy Current Separator (ECS) with Quick Change belt system at WasteExpo 2018 in Las Vegas.

RevX-E Eddy Current Separators offer a direct drive for both the rotor and conveyor. Larger side panels allow complete open access to the ECS conveyor for easier maintenance. The hood with adjustable splitter gives customers the ability to switch back and forth between the fines adjustment for processing small particles and the rack and pinion adjustment for coarse materials. Recycling Product Manager Chris Ramsdell said in a statement that “these time- and labor-saving features will have an immediate positive impact on a customer’s bottom line.”

Designed for separation of nonferrous metals, the RevX-E Eddy Current Separator is ideally suited for an array of applications, including ASR processing, purifying glass cullet and plastics and nonferrous recovery from bottom ash. It features an eccentrically mounted magnetic rotor within a non-conductive larger diameter shell. This eccentric rotor concentrates its eddy current forces into a zone of separation at the end of the belt. “By focusing its field, this design ignores ferrous material in the flow,” said Ramsdell in a statement. “Our eccentric rotor design effectively reduces long-term wear caused by heated ferrous buildup.”

Units are available in 1, 1.2 and 1.5 meter widths and can be configured with a heavy-duty vibratory feeder, feeder support framework, separation shroud/splitter and controls for turnkey installation. Eriez also offers two rotor configurations, enabling users to choose the right model for their specific application requirements. The ST22 rotor is designed for sorting material less than 1-inch, and the LT2 rotor design is applicable for sorting material 1-inch and larger.

Fairbanks Scales to Showcase Weighing Innovations at WasteExpo 2018

Fairbanks Scales, Inc., the oldest scale company in the U.S., and the world’s leader in weighing equipment, will be showcasing a wealth of state-of-the-art industrial scales at WasteExpo 2018. Visit booth #1028 in the Las Vegas Convention Center to view Fairbanks Scales’ latest groundbreaking innovations in weighing equipment, including the Talon HVX heavy-duty truck scale, equipped with the innovative Intalogix Lightning/Power Surge Protection system. The HVX Cut-a-way Field Pour will be on display at the Fairbanks booth, along with the Fairbanks Access Solutions (FBAS) Entry Station and the 1605RF remote display.

Talon HVX (Highway Vehicle Extreme) scales are built to federal bridge standards, with incredibly strong modules boasting the lowest deflection in the industry. Load cells are provided with armored stainless steel cabling for durability and hermetically sealed for moisture protection and 25-year warranty. Talon scales are equipped with the proprietary Intalogix lightning protection system. Designed and developed exclusively by Fairbanks, this state-of-the-art technology has a true digital signal, up to one million times stronger than a conventional analog signal, which protects the scale from any harmful surges or electrical spikes.

The Fairbanks Access Solutions (FBAS) Entry Station greets vehicles with a visible and audio prompt, quickly capturing essential transaction information and sending it to the MatreX Processing System, which relays real-time information to the driver.

Also featured is the rugged and durable 1605RF Remote Display, which has a NEMA 3 rated enclosure for outdoor use, and a wireless data interface that eliminates the need for cabling between the scale instrument and the remote display.

The FB2550 instrument to be highlighted includes even more features, functionality and connectivity for today’s truck weighing applications. Standard features include onscreen IP camera interface, full color touch screen display, Ethernet connectivity and transaction reports via email.

About the Author

You May Also Like