Digitalization Presents New Opportunities for the Waste Industry

Operational deficiencies in collection and transfer significantly impact a waste management company’s bottom line, especially when it comes to roll-off dumpsters – from location to usage.

The right technology could optimize pickups, manage assets and track collections, but the wrong solution can be expensive and time-consuming to implement and maintain.

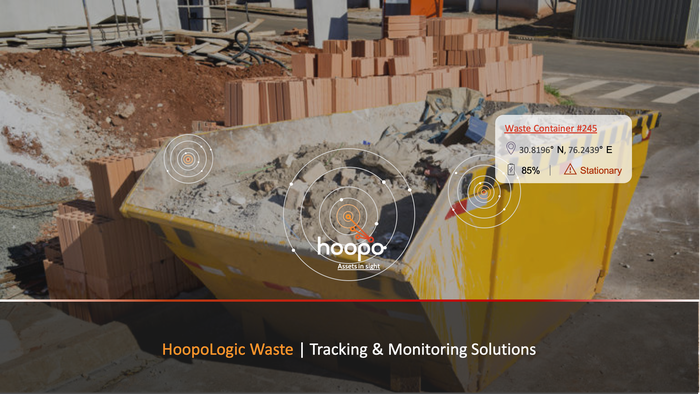

Israel-based hoopo recently introduced a low-power, wide-area (LPWA) tracking solution, hoopoWaste, aimed at alleviating common problems for roll-off dumpster management – with a battery life of three to eight years.

Ittay Hayut, hoopo co-founder, spoke with Waste360 about the company’s tracking technology and what these low-cost innovations could mean for the waste industry.

Waste360: How did you identify this problem for the waste industry and create the solution?

Hayut: The place where we started from is from the team that founded this company, myself and four other co-founders. We are experts in the field of radio and low-power location, low-power tracking. And in the growing world of logistics, there's a growing need for visibility to be able to detect the blind spots in which inefficiency lies and money or time goes to waste.

It was obvious to us that we can create a very unique and low-power tracking technology. And the reason that we believe it's extremely important is that a lot of the costs of tracking technologies are because the solutions are consuming a lot of power. If you think about it, if even if you wanted to track something of your own, whether it's the remote control of the TV, or perhaps your car's keys, one of the things that you wouldn't want to have is something that needs recharging a battery replacement every other day. It makes your life very difficult. And you know, if you're a logistics company, or a waste management company that handles thousands to tens of thousands of non-motorized assets, you cannot really afford to go and replace the batteries all day long. And so, it was obvious to us that we need to create a very power-efficient and cost-sensitive tracking technology, which is where we started from.

Following that was the question of it's not only enough to develop a good technology, but you need to build a good product on top of this technology. And you need to not only make sure that you create tracking and visibility for assets; you also need to make sure that you're providing the right kind of analytics and insights for the partners that you work with.

It could be the same solution that will track dollies in airports, and the same solution that will track rolling dumpsters in a waste management business. But the behavior of the assets, the insights that we generate the analytics are a little different. And when it comes to roll-off dumpsters, there's a big need from all the sides of the equation. It could be waste contractors. It could be waste recycling companies. It could be the local authorities or municipalities or the regulations that want to prevent illegal disposal. And all the interests align from no matter where you look from in the market.

One of the challenges with tracking these dumpsters is that again, you need to have something that once you install it, you forget about its existence for several years because if you have to keep track of it in order to maintain the solution or replace the batteries, it will just not work. And this is how we got into this business.

We had our first construction waste recycling company as a customer here in Israel. And we started from that we learned about the business – we added features to the solution. So nowadays, we can even detect disposal events without using any camera or level-based tools that are very expensive, just on the own based on the movement of the asset. And we started from there. We grew to hundreds of devices and to working with different municipalities, waste contractors etc. And we find this market to be very, very interesting for us.

Waste360: What were the specific issues the Israel waste company was having, and how can that apply to other businesses on a global level?

Hayut: We think there are three different types of users in the waste or dumpster management business. There are small, family-owned businesses that manage only a few dumpsters. They have their contractor friends and they managed the containers by themselves. They don't need to worry too much about their location. But then you have two other tiers in the market. The second tier is companies that manage hundreds of containers, and they are growing, and they want to create more business for themselves. And one of the things that they want to do – this is the example for the first customer we had in Israel – they wanted to improve utilization of their assets. They wanted to make sure that they utilize the assets in a way that they could make as many customers and provide the best quality of services they can.

What [the Israeli company] did before us is they used pen and paper. And this is what the vast majority of the market does. They use pen and paper to remember where the assets are placed. If someone takes their dumpster and uses it for another site, or disposes of it in a certain area, they will probably never know that it happened. And this is where [the company] started coming from. Afterwards, [the company] also realized that if they specifically were a recycling company, that it's very crucial to make sure that the waste that they bring into their recycling center comes from the right place because if it comes from another place with a different kind of waste, it could delay the recycling process and that's their core business. So, it's really all about resolving inefficiencies and the mishandling of waste and improving utilization.

The last tier of the market, which is the huge companies that manage or lease tens of thousands of containers, they want to have a very sophisticated system. So that it could even besides all the things that we discussed up to now, it could also allow them to rent the dumpsters to other companies on a pay-per-use basis because only if they have they now have the visibility and they know exactly what usage has is being done with their assets, then they can build the customers exactly for what they do with it. So, it's all about creating data, which can then be analyzed in ways that weren't possible before and then create actionable insights and actionable data that will eventually help. It actually helps the world because it reduces not necessary emissions. When you route yourself to pick up a trailer or you look after it, it eliminates unnecessary yard hunts.

Waste360: What implications, if any, are there for cybersecurity?

Hayut: Most of our founders spent several years in different intelligence units in the military, and we definitely put a lot of effort to make sure that the system is reliable and secure. In essence, we're using standard communication protocols. The communication we're using in most areas is standard protocols, whether it's LORA or NB IoT, which is a cellular-based communication protocol. The thing that is important to note about the solution is that there are plenty of GPS and cellular-based tracking solutions. And when you use GPS and traditional cellular solutions, you end up with a very expensive solution that doesn't last for very long from the battery perspective. The uniqueness of our solution is that we're using a suite of Low-Power, Wide Area (LPWA) technologies. With that, we're capable of achieving three to eight years of battery life while using regular AA batteries.

Waste360: Where do you see this technology moving in the next five to ten years?

Hayut: In any logistics business, whether it's supply chain airport logistics or waste management, the future lies in autonomous systems. And when we say autonomous systems, it doesn't necessarily mean autonomous vehicles or autonomous driving systems. What we're actually talking about is, you wouldn't need to think about which container or which dumpster you need to collect from where – you will have AI-based systems and AI predictions and machine learning that will help you make sure that you optimize your processes to the best efficiency that you can. However, you cannot do this without the underlying data. You cannot predict from where or what time to collect something if you don't know where it's located. So, I think the future is really about the digitalization of any asset in your supply chain or waste business. And we're planning to connect more assets in the next you know, few years, hopefully in five to 10 years. Most of the assets in the business will be connected.

About the Author

You May Also Like