November Fire Report: Talking Battery Safety with ERI’s John Shegerian

The market for battery recycling is moving towards circularity with a push to recover critical minerals and commodities. Watch as Ryan Fogelman of Fire Rover discusses battery safety and the current state of recycling with ERI's John Shegerian.

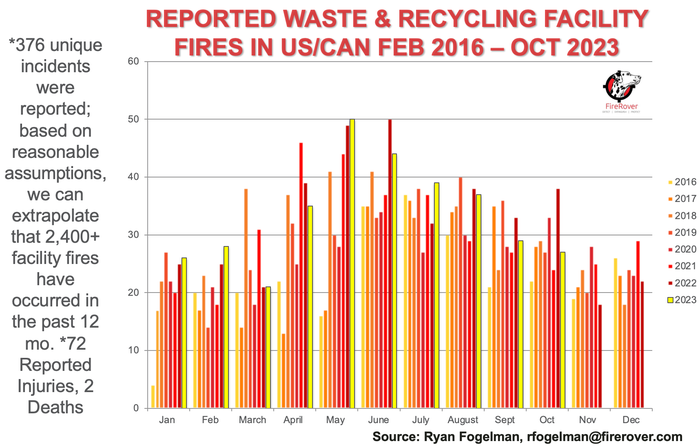

In October, we encountered 27 publicly reported fire incidents at our waste and recycling facilities. Of those incidents, 16 occurred at waste, paper and plastic facilities and 11 occurred at scrap metal recycling facilities. At Fire Rover, we responded to 300-plus hot spots and/or fire incidents at our clients’ facilities.

As you can see from the data, we typically trended down in most of the past Octobers, coming off the highs of the “summertime spike” in fires we usually see in the preceding months. However, October is considered a low month, even by October standards, which is refreshing to see.

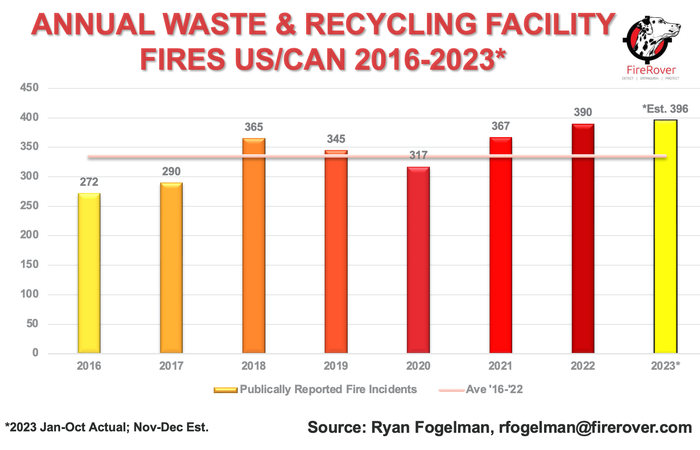

Another positive is the forecasted number of publicly reported fires for this year has come down slightly. We are currently on trend to end at 396 fire incidents, which is higher than last year, but if we have a low November or December, we could easily fall below that number and end at less than last year.

Battery Recycling Versus Battery Reuse

A few weeks ago, I was part of a battery recycling panel with Bob Shallenberger from Interco and Christina Chilcote from Blue Whale Materials at the Automotive Recyclers Association Convention & Expo. During that presentation, which you can watch below, Shallenberger and Chilcote were questioned hard by a man who sells a solution that works for the “reuse” side of the business. Due to his line of work, he automatically thinks recycling is a step too soon and should only be used as a last resort, when in reality all of us in the battery recycling industry would love to see a healthy and safe marketplace for electric vehicle and personal storage batteries to be resold and reused. The proper term here is “safely.”

Currently, the batteries that are not recycled or reused are either getting knowingly and unknowingly placed into waste and recycling streams and causing fires at our waste and recycling facilities or exploding in people's homes and apartments. We also need to get the material out of those batteries to help provide a supply of nickel, copper and other rare earth metals needed to continue to supply the ever-growing requirement for more batteries. In reality, there are a ton of great companies out there that have been properly collecting and recycling batteries for a long time.

This month, I was fortunate to connect with John Shegerian, one of those longtime operators and the co-founder of Electronic Recycling International (ERI), the largest electronics and IT asset disposition service provider and recycler of e-waste in the United States. He and I spoke about ERI’s mission and how it fights the inherent risk of fires in its business.

If you had to explain who John Shegerian is in one word, what would it be and why?

Shegerian: Unstoppable. Throughout my life and my career as a serial social entrepreneur, I’ve viewed obstacles and challenges as opportunities. It’s the foundation of the business we built with ERI—taking a societal problem that the majority viewed as unsolvable and turning it into a solution- and innovation-driven opportunity

Walk us through how you started ERI and what it does from a sustainability perspective.

Shegerian: In 2002, my friend and future business partner Aaron Blum launched a small electronics recycling company. After two years, he turned to me for advice. Having just sold FinancialAid.com, I loved the idea of recycling electronics but agreed with Blum we needed to find a way to make it a profitable venture. The first step I took was bringing my wife Tammy and business colleague Kevin J. Dillon into the fold. The four of us would become the founders of ERI.

We got out of the innovation gate early—setting new standards for a growing industry with barcodes for tracking electric components, overhead cameras, totally green facilities with electric forklifts and recycled furniture. From the beginning, our team wanted to do everything the right way.

Within three years, business was thriving, and we started an expansion to additional facilities so we could serve the entire country. While ERI continued to focus on end-of-life electronics recycling, our facilities soon also added ITAD to their services. This would help businesses recover asset value from obsolete electronics and help provide a second life for many of these working devices.

Through groundbreaking innovation, strategic partnerships, radical transparency and a steadfast commitment to the circular economy, we work every day to keep toxins out of landfills, keep data private and safe and do everything with a vision for zero waste, zero landfill and zero emissions.

As a recycler, we are in the sustainability business. Focusing on recovery of reusable assets followed by the recycling of critical commodities. We continue to focus on sustainability through our growth as we enter strategic partnerships directly with our down streams to ensure outlets for our needed commodities, work to enhance convenient recycling options for consumers throughout the country, work to minimize truck miles, make our facilities more efficient and become the country’s first carbon neutral e-waste company.

Where do you see the market heading from a recycling/reuse perspective?

Shegerian: The market is heading in the direction of circularity, critical mineral and commodity recovery and radical transparency. There is a real push to recover critical minerals and commodities like copper, aluminum, lithium and cobalt as these materials are crucial for the decarbonization of our economy.

How do you think the U.S. is doing compared to the rest of the world? And where do you feel our battery recycling infrastructure needs to be in the future?

Shegerian: In many ways, the U.S. is leading the way. For example, the U.S. Department of Energy is now funding and encouraging the domestication of critical resource recovery. This will pay massive dividends to the U.S. in the immediate years as well as on a long-term basis. Secondarily, when you look at the innovations coming from companies like Redwood Materials and the forementioned federal investments being disbursed, these kinds of advancements are not happening anywhere else in the world.

Where does safety fit in at ERI?

Shegerian:The health and safety of our employees and partners is first and foremost. Recycling electronics is considered a high-hazard industry by the Centers for Disease Control and Prevention and Occupational Safety and Health Administration (OSHA). ERI has successfully maintained OSHA injury recordable rates and insurance experience modification rates well below the national average. All ERI facilities have trained and dedicated environmental, health and safety (EHS) personnel. Our EHS staff thoroughly train all employees year-round on the hazards of their jobs and are a constant present around the facility to abate all hazards.

We’ve seen time and time again how catastrophic battery fires can destroy entire buildings. So, safety preparedness through both training and installation of systems such as Fire Rover is a top priority at the company. This preparedness has already proven to be incredibly valuable.

You deal with the fire risk from batteries daily. What advice or best practices would you give to an operator of a transfer station, scrap metal or recycling operation?

Shegerian:One key piece of advice pertaining to batteries in e-waste is to understand your job is not just to prevent but to minimize and manage battery fires. They’re happening, and no one is entirely immune to them. So, it is critical to train employees; add detection, suppression systems and monitoring systems; focus on the obvious points where fires may happen; and ensure you consider areas that are less likely to have fires. Then keep up the training. Employees can sometimes look for shortcuts, so you must stay diligent.

It's also important to conduct trainings and multiple drills geared toward battery identification, handling and storage. Our fire response drills consist of various scenarios that could pose safety risks to our employees, the public and our facility infrastructure. All ERI facilities have a fire response team whose members conduct monthly hands-on training. The main focus of these training sessions is the response time for operating our fire suppression equipment to achieve the best possible results.

Conclusion

If you would like to hear more, Shegerian had me as a guest on his “Impact with John Shegerian” podcast. He started the podcast in 2009 and has some amazing discussion around impact and innovation. You can listen to and watch the full podcast episode here:

Have a safe and fantastic Thanksgiving, and remember, you can never be too careful frying those turkeys!

Ryan Fogelman, JD/MBA, is vice president of strategic partnerships for Fire Rover. He is focused on bringing innovative safety solutions to market, and two of his solutions have won the distinguished Edison Innovation Award for Industrial Safety and Consumer Products. He has been compiling and publishing the “Reported Waste & Recycling Facility Fires In The US/CAN” since February 2016 and the “Waste & Recycling Facility Fires Annual Report.” Fogelman regularly speaks on the topic of the scope of fire problems facing the waste and recycling industries, early detection solutions, proper fire planning and early-stage fire risk mitigation. Additionally, Fogelman is on the National Fire Protection Association’s Technical Committee for Hazard Materials. (Connect with Ryan on LinkedIn at https://www.linkedin.com/in/ryanjayfogelman or email at [email protected])

About the Author

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)