Waste & Recycling’s Frontline: A Toxicologist’s Perspective

The materials we process at our waste and recycling facilities can present both physical and health hazards that range from minimal to severe. One hazard can be found in batteries, which contain gases that are highly flammable and toxic.

The materials we process at our waste and recycling facilities can present both physical and health hazards that range from minimal to severe. One hazard can be found in batteries, which contain gases that are highly flammable and toxic. The type of gas released depends on the battery chemistry involved but typically includes carbon monoxide, carbon dioxide, hydrogen, methane, ethane and other hydrocarbons. In this month's article, we sit down with a career toxicologist to better understand what can be done to protect our frontline workers and fire professionals from the threats they face due to the materials they handle.

Since I began working in this industry in 2015, I have had a concern I cannot get out of my head: The dangers of lithium-ion batteries, which can shoot shrapnel when they hit thermal runaway or explode. This very thing happened in the below video when a loader ran over an electric bike battery.

Knowing this danger, why are companies selling lithium-ion battery-specific fire extinguishers where the person fighting the fire must be standing within mere feet of the hazard? Add to that the dangers of the potential toxic off-gas exposure when fighting a fire at a close distance. There is no scenario where I suggest standing within six feet of a hazard with a handheld fire extinguisher in an effort to fight a lithium-ion battery fire.

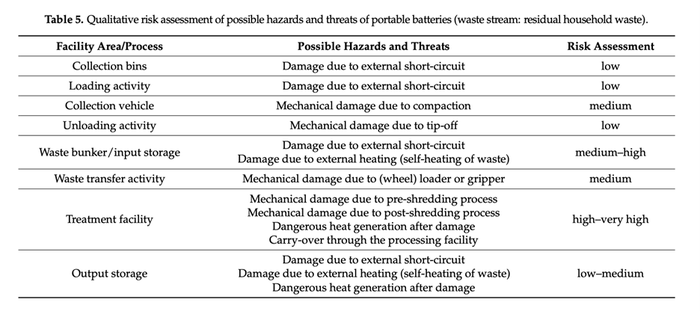

In an Austrian study, “Lithium-Ion Batteries as Ignition Sources in Waste Treatment Processes—A Semi-Quantitate Risk Analysis and Assessment of Battery-Caused Waste Fires,” the research team developed the following table that separated the processing activity by the possible threats and subsequent risk assessment. Most lithium-ion battery fire incidents occur within collection vehicles, on tipping floors, during consolidating and processing and once in finished product storage.

The same study concludes:

No other substance or material has ever comparably endangered the whole waste industry. Hence, besides research and development activities for investigating and understanding the hazards and risks of lithium-based portable batteries, increased technological development and innovation efforts are indispensable for reducing the risk potential of end-of-life portable batteries. To minimize risks, the waste sector must aim to source-segregate as many batteries as possible via separate collection systems and take-back schemes. These options help ensure a reduced or damage-free return system. That requires increased efforts in public relations and consumer awareness. However, a 100% separate collection rate for portable batteries is highly unrealistic without a comprehensive deposit system. Hence, operators of treatment facilities have to find ways to […] protect critical infrastructure and treatment processes (e.g., including new detection and extinguishing methods) or … detect and separate portable batteries during their treatment processes.

I have been searching for studies or reports on these hazards for years, but there has been very little research done on the potential dangers that those of us who fight fires on the frontlines are contending with.

Last month, as I was working on my updated annual report, I received a direct message from Dr. George Thompson, a toxicologist with more than 50 years of experience in chemical, product and process hazard and risk assessments. He has published 22 hazardous chemical books, organized four national or worldwide conferences, given hundreds of technical presentations over his distinguished career and developed the largest relational chemical and product databases in the world. He also has served as an expert witness in 54 cases and spent a considerable time analyzing the highly hazardous chemicals released into the air at the East Palestine, Ohio, train derailment and fire.

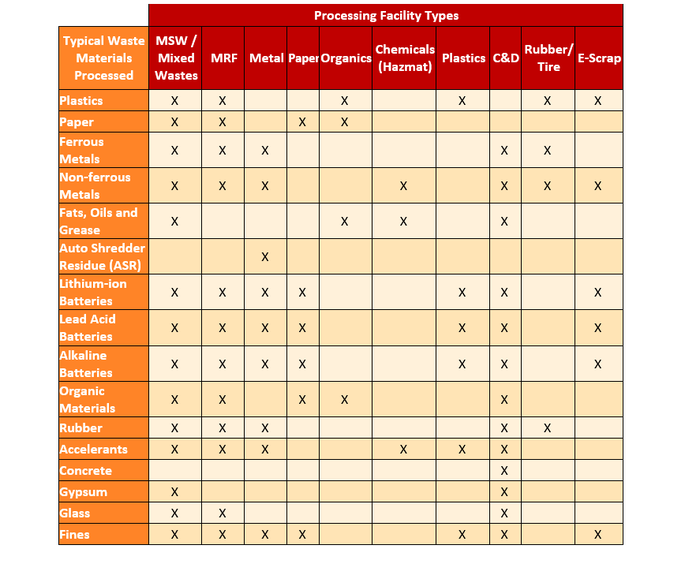

So, I asked Thompson if he knew anything about lithium-ion battery fires and the potential dangers of their off gasses during and after thermal runaway. He offered to take a stab at outlining the potential hazards we face while fighting these fires. Based on industry experience and my observation working with Fire Rover to address fire incidents at waste and recycling facilities, the common materials processed by and therefore potentially exposed to at various waste processing facilities are described in the table below.

What are the Materials and Potential Effects of These on Frontline Workers and Fire Professionals?

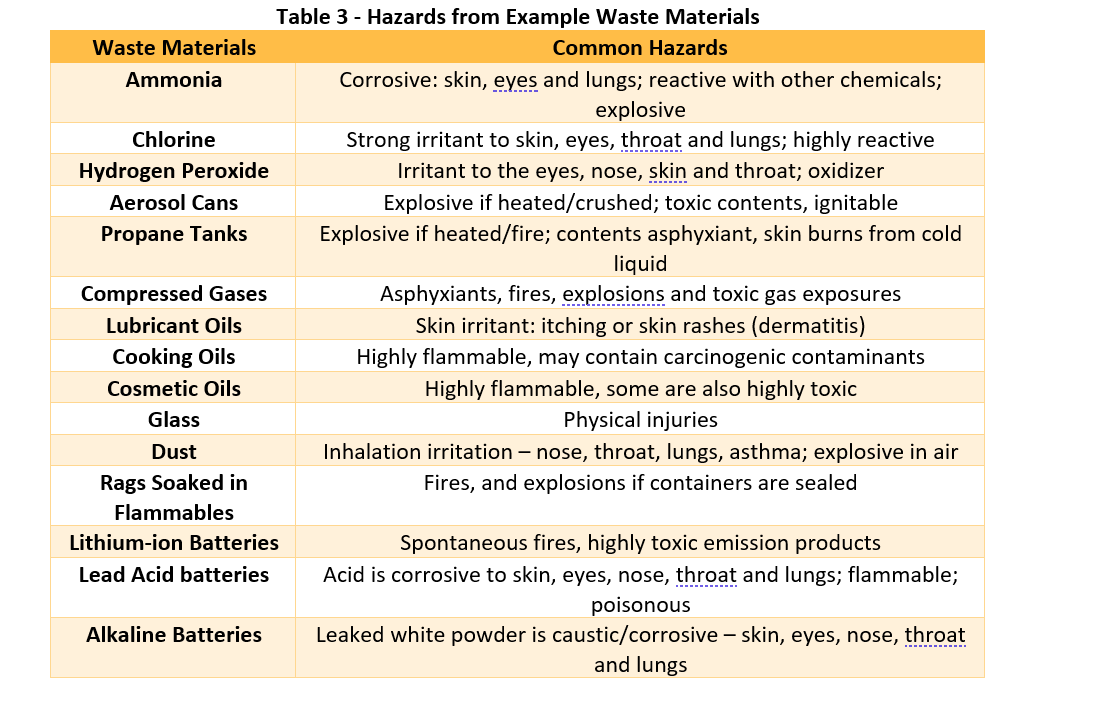

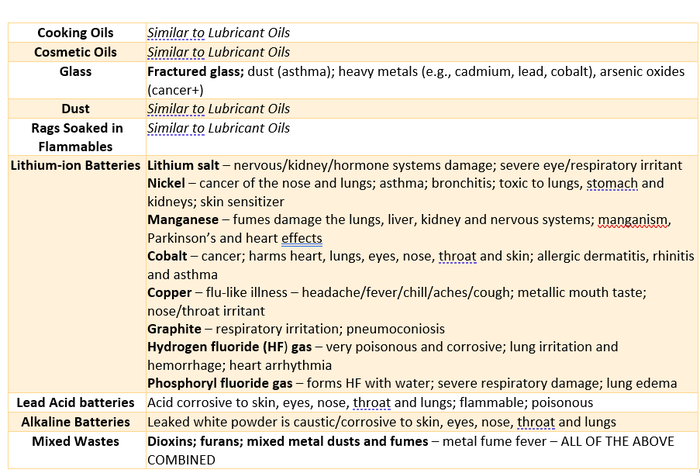

Thompson: Processing waste and recycling materials presents inherent risks to workers, emergency responders and the environment. The spectrum of materials to be processed includes almost anything in commerce. Some potentially hazardous materials include chemicals (e.g., ammonia, chlorine, hydrogen peroxide), pressurized containers (e.g., aerosol cans, propane tanks, compressed gases), oils (lubricant, cooking, cosmetics), glass, dust, rags soaked in flammable liquids and batteries (e.g., lithium-ion, lead acid, alkaline).

Additional types of processed materials can include rubber, concrete, gypsum and other building products. As indicated in Table 3 below, common hazards associated with the initial materials are also quite broad. Physical hazard descriptors for this selected list of waste materials include explosive, oxidizer, reactive/highly reactive, ignitable, flammable/highly flammable and even spontaneous fires. Personal health hazard descriptors are even more comprehensive, ranging from corrosive to asthma, poisonous, irritants/strong irritants, toxic/highly toxic, asphyxiants, carcinogenic and caustic.

What is Your Advice for Protecting Frontline Workers and Fire Professionals?

Thompson: Since both physical and health hazards associated with these materials are potentially severe, the best protection for employees, their associates, the community and the environment is awareness—knowledge and best practices learned through training and supervised experience, not from accidents and injuries!

The first step is for each employee to learn the hazard vocabulary. For example, what is the difference between the following terms:

Corrosive, irritant and caustic

Flammable, highly flammable, spontaneous fire and oxidizer

Reactive, highly reactive and explosive

Toxic, highly toxic, poisonous, carcinogenic and asphyxiant

Dermatitis, asthma and asphyxiant

Once these definitions are understood, the second step to greater personal, associate, community and environmental safety is correctly associating each hazard with the processed waste material. Obviously, “highly” materials must be handled more consciously than other materials.

The third step in improving safety and avoiding accidents is to learn what personal protective equipment is needed to handle each type of hazardous waste material. Corrosive or irritating materials may require appropriate gloves, safety glasses, goggles or coveralls. Any flammable or potentially explosive waste materials warrant spark-avoidance barriers and perhaps grounding resources before they are processed.

Appropriate breathing protection is warranted for flammables, corrosives, irritants, caustics, asphyxiants and carcinogens. Finally, waste materials that are reactive, oxidizers or explosives must be processed separately to avoid mixing with incompatible materials that will result in unintended consequences. Implementation of a formal employee training program, starting with initial employment, will significantly minimize the risk of either physical or health accidents and injuries.

What are the Increased Hazards When a Fire or Explosion is Introduced into the Equation?

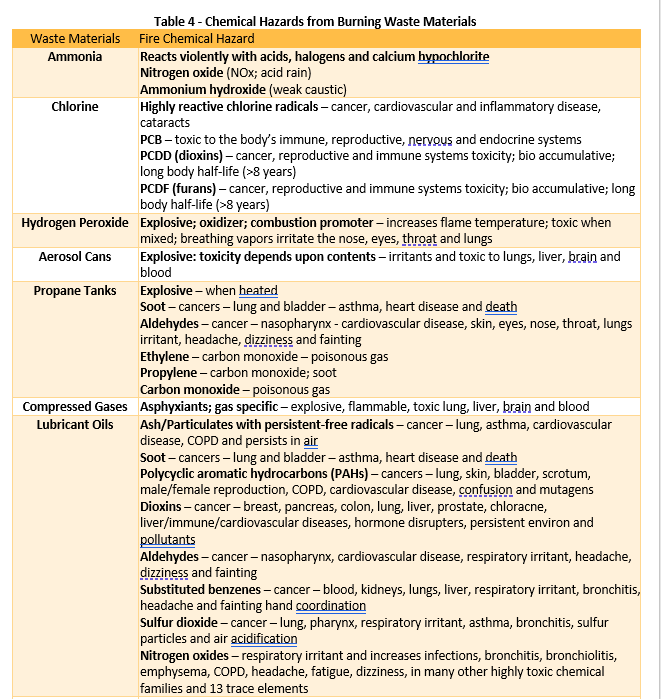

Thompson: As formidable as the many types of waste materials processed daily can be, their hazards during and following a fire are much greater. Table A above lists 15 selected waste materials and their common hazards. In a fire, these 15 waste materials become more than 70 fire chemical hazards (see Table 4 below).

Fire breaks down each waste material into various chemical products that multiply the hazards multiple fold. These risks are not only much greater for the employees but also for the associates, community and environment. Preventing fires in waste and recycling facilities becomes an extremely high priority!

Fire chemical hazards from waste materials are more numerous than those of raw waste materials but are also more severe and profound. Responsible management of a waste or recycling facility must not only provide appropriate personal protective equipment in case of a fire in their facility, but they must also educate and train local firefighters and other emergency responders to ensure they are adequately equipped and knowledgeable in case of a waste material fire. Local first responders are often volunteers and minimally equipped and undertrained. As a result, they can be exposed to severe, life-threatening exposures from a waste materials fire that can shorten their lives. Preparation through training and equipment acquisition are the keys to maintaining maximum safety and health for all.

Conclusion

Thompson’s insight and candor around these materials was undoubtedly an eye opener for me. I do not share these to scare anyone, but safety knows no competition, and understanding these hazards is the first step in being a great operator.

In last month’s article, “Taming the Li-Ion: Why U.S. and Canadian Operators Lead the World in Containment of Lithium-ion Battery Hazards in Our Waste and Recycling Streams,” I focused on why the U.S. and Canadian operators took the bull by the horns when dealing with fire hazards, which is why they are on the forefront in the world of getting lithium-ion battery hazards under control at our facilities. But we cannot stop now. Safety must stay the No. 1 priority for our operators to ensure we do everything we can to protect our employees and the fire professionals who protect our operations.

If you are attending WasteExpo 2024 in Las Vegas, Thompson will be joining me and an all-star panel that includes David DeVito from ReSource Waste Services; Bob Shallenberger from Interco; and Scott Ledford from Metrosite Inc. to discuss “Dealing with Lithium-ion Battery Fires on the Frontlines” on Monday, May 6 at 3:30 p.m. MST.

Additionally, my work on the “7th Annual Reported Waste & Recycling Facility Fires Report” is almost complete. I am set to release the new report while simultaneously hosting a webinar to review my findings on March 12 at 1 p.m. ET. You can register for the webinar here; space is limited. If you would like to reserve a digital copy of my report upon release, you can enter your information at https://lnkd.in/dgAX9Ze or subscribe to my LinkedIn 🔥 Fire Safety Report 🔥 newsletter at https://lnkd.in/gjwNpSph.

Ryan Fogelman, JD/MBA, is vice president of strategic partnerships for Fire Rover. He is focused on bringing innovative safety solutions to market, and two of his solutions have won the distinguished Edison Innovation Award for Industrial Safety and Consumer Products. He has been compiling and publishing the “Reported Waste & Recycling Facility Fires In The US/CAN” since February 2016 and the “Waste & Recycling Facility Fires Annual Report.” Fogelman regularly speaks on the topic of the scope of fire problems facing the waste and recycling industries, early detection solutions, proper fire planning and early-stage fire risk mitigation. Additionally, Fogelman is on the National Fire Protection Association’s Technical Committee for Hazard Materials. (Connect with Ryan on LinkedIn at https://www.linkedin.com/in/ryanjayfogelman or email at [email protected])

About the Author

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)