Undressing the Current State & Future of Textile Recycling in the U.S.

Today, Resource Recycling Systems (RRS) releases its white paper on “Textile Recovery in the U.S.: A Roadmap to Circularity,” which highlights the current state of textile waste in the U.S. and outlines “a future-state system in which textiles are recovered for best and highest use.”

In the preface, CEO Jim Frey notes that, “As one of the fastest growing waste streams, used textiles are a largely untapped resource. Recovering these fabrics and fibers as inputs to a variety of closed loop and cascading end uses presents the opportunity to develop more sustainable and resilient supply chains. The time is ripe for action throughout the industry value chain to transform textile manufacturing, use, and recovery into a truly sustainable and resilient system.

Marisa Adler, Senior Consultant at RRS and lead author of the white paper, told Waste360 that, “The goal is to bring people to a common understanding and conversation” around the topic of textile waste and recovery; to “create a baseline level of understanding and recognition of the need for scalable systems solutions.” And, “What’s really exciting is that there’s a lot of buzz around this now, and people are finally giving attention to the problem of textile waste.”

In order to ensure that the white paper “depicted the current state of reality accurately and soundly,” per Adler, it was reviewed by industry leaders including representatives from Worn Again Technologies, Ralph Lauren, IKEA Retail US, Circular Systems, Secondary Materials and Recycled Textiles (SMART) Association, Closed Loop Partners, Tyton BioSciences, and the Sustainable Furnishings Council. This input was sought in order to make sure the correct gaps and details were being captured, and that the solution concepts made sense to industry stakeholders.

The white paper lays out the current state and growth of textiles in the U.S. waste steam; explores the role of fast fashion; looks at the textile-waste stream by material type and fiber composition; details the elements of a sustainable recovery system; and offers a way forward to a new U.S. textile recovery system.

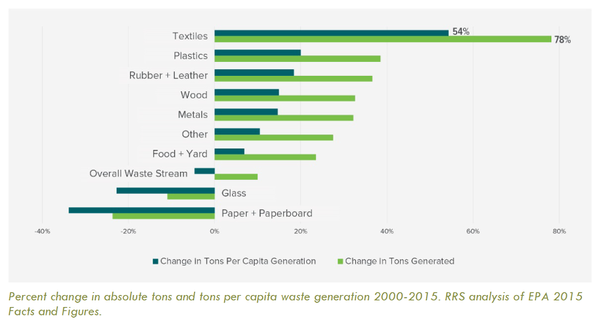

RRS observes that the growth of textile waste in the United States is “outpacing the growth of every other major category of waste” (as shown in the graph below). Between 2000 and 2017, textile waste increased 54 percent per person, on a per capita basis, while overall waste generation decreased by five percent. Thus, “solving for textile waste in the United States can have a measurable global impact on the upstream investment of human and natural capital like oil, cotton, energy, water, and chemicals used to make textile products.”

Adler recognizes the need for “very practical solutions on how we can fill the gaps in information and infrastructure.” One example she mentions is that, though the U.S. Environmental Protection Agency (EPA) tracks how much textile waste is generated year over year, “there is no current data that tell us the fiber composition and frequency and volume of blend within that waste stream. And that’s the information we need to know in order for textile recyclers to develop, build, and scale their facilities.” So, the white paper “lays out that we need to conduct waste characterization studies of the commercial and the residential waste streams, both post-industrial, pre-consumer, and post-consumer—to create those foundational data sets that can then be used to build the rest of the system.”

On the infrastructure side, Adler says that, “Just like we have material recovery facilities (MRFs) for traditional curbside recyclables, we need something similar to that for textiles, with sorting capabilities.” The white paper “proposes the concept of a textile MRF, which starts with reuse. It would sort for quality first and then by fiber type and other emerging identification technologies.”

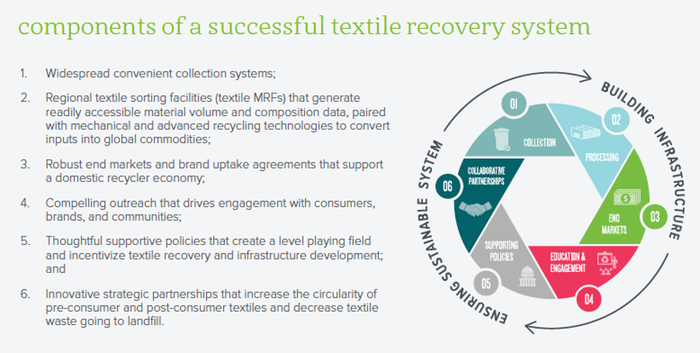

RRS asserts that a sustainable recovery system must have a strong foundation across six key elements (as summarized in the graphic below):

Collection

Processing

end markets

education & engagement

supportive policies

collaborative partnerships.

The white paper digs into each of these areas with relevant data and recommendations.

Elaborating on the issue of policy, Adler observes that, “The fashion industry doesn’t traditionally have big budgets for research and development—so it’s hard for them to invest in testing and piloting and scaling recovery systems ideas, but if there were a policy that helped level the playing field and leveraged collective investment, that could be really helpful.”

The white paper serves as a call to action for collaboration “across the textile and apparel value chain to address consumption and waste generation, reduce impact on the environment, and develop more sustainable models to manage this rapidly growing waste stream.” And it concludes that, “Progress toward an ideal future state starts with establishing foundational elements and developing sustainable solutions step by step.”

Adler says the ideas laid out in the white paper are “ambitious but absolutely doable and critical.” She also observes that, “There is a lot of room for traditional haulers to engage in the space. There is so much textile waste available for collection and recycle and reuse. Right now we are just throwing away textiles that are feedstock for supply chains.”

About the Author

You May Also Like