4th Annual Reported Waste & Recycling Facility Fires in the US/Canada Released

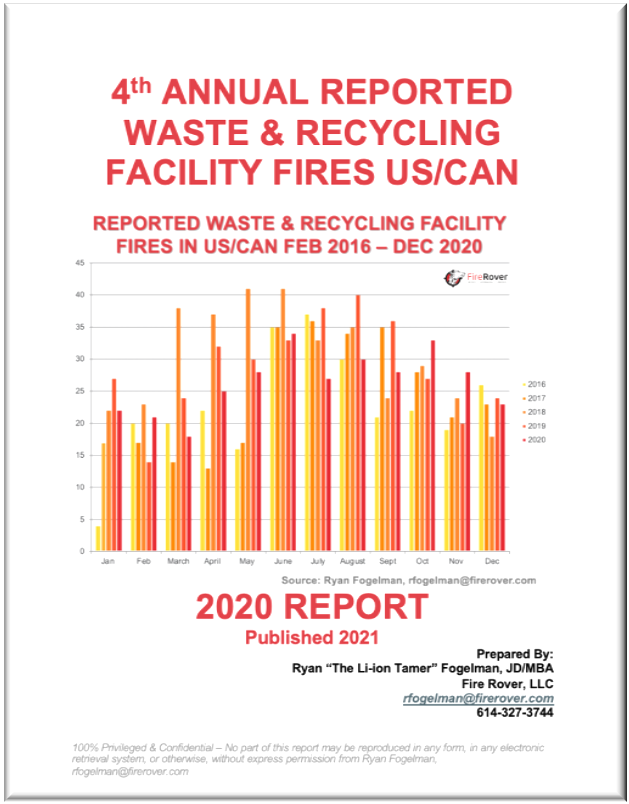

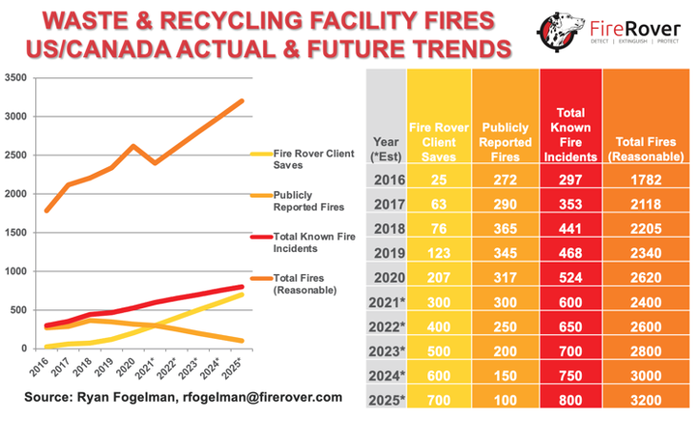

I am sure you are sick of hearing that 2020 was a year like we have never experienced in human history. The global pandemic has forced “change” across the globe that has affected all aspects of our lives including waste and recycling. I could spend the entire report focused on the aberrations we experienced in the industry from a fire perspective in the past year. March saw a drop of incidents, and then we experienced a gradual increase each month until July, where we had the lowest level of fire incidents since 2016 during the traditional summertime spike. We also experienced two of the highest months for fires—October and November—that were likely due to the increase in residential tonnage versus commercial tonnage.

Instead of focusing on what was different in 2020, I want to take a more strategic view and focus on the trends we have seen since 2016. This report will highlight our collective experience in the waste and recycling industry, as well as our approaches to solving these problems. Additionally, it will outline what has worked, what hasn’t worked and how we are going to move forward.

When I was first introduced to the industry, fires were our dirty little secret. We had been having fire incidents since the beginning of time, but as an industry, the lithium-ion (Li-ion) battery wave really threw us for a loop. I saw the writing on the wall in 2016 and 2017, but in 2018, we experienced the crash of lithium-ion batteries in waste streams across the globe, from Japan, Austria, Sweden France, Germany, UK, Australia, Canada, and the U.S.

To say we were caught off guard is an understatement. Experts in disaster response typically prepare for the worst incident’s society has experienced in our history. But we cannot look backward. We are seeing a transformation in how we as a society engage and interact with power. Just as the internal combustion engine drove our industrial revolution, lithium-ion battery technology is forcing us to reimagine how we can improve our lives by having power at our fingertips.

With this power evolution comes dangers, specifically to our industry, that are in the form of fires. And most of the dangers are unfairly falling on the waste and recycling operators, the local fire authorities and the public who have to deal with the issue without the help of government or, most importantly, the manufacturers that are making profits hand over fist as they continue to feed the beast driven by our never-ending appetite for cordless power.

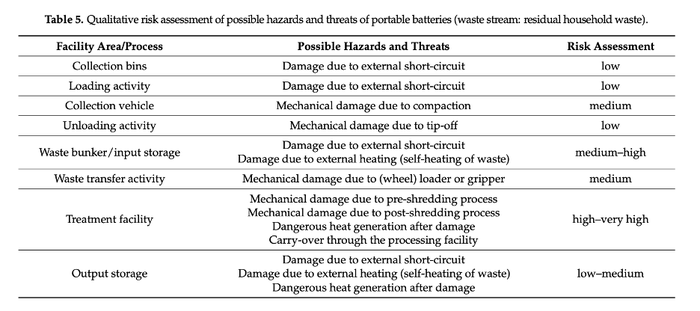

In a recently published Austrian study called “Lithium-Ion Batteries as Ignition Sources in Waste Treatment Processes—A Semi-Quantitate Risk Analysis and Assessment of Battery-Caused Waste Fires,” the research team developed the following table that separated the process activity by the possible threats and subsequent risk assessment. It is clear that the most fire incidents occur within the collection vehicles, on the tipping floors, during consolidating and processing and once in finished product storage.

The study concluded that “the risk of lithium-based portable batteries is significantly too high, which makes it difficult to maintain modern waste management in a sustainable way. Primarily, municipal solid waste treatment plants are at increased risk. The probability that treatment plants burn to the ground is far too high, according to the available assessment. The increased number of major fires in waste management in recent years is clear and undeniable evidence.”

The manufacturers are spending a ton on lobbying governments based on their overall safety record (outside of the EOL and waste and recycling hazards) as well as providing funding for associations like Call2Recycle that focus on educating the public about the proper disposal of batteries. Although it is great to provide more recycling centers and do all we can to drive proper lithium-ion battery disposal, the producers stand silent on the most important issue: the cost batteries have on our waste and recycling stream.

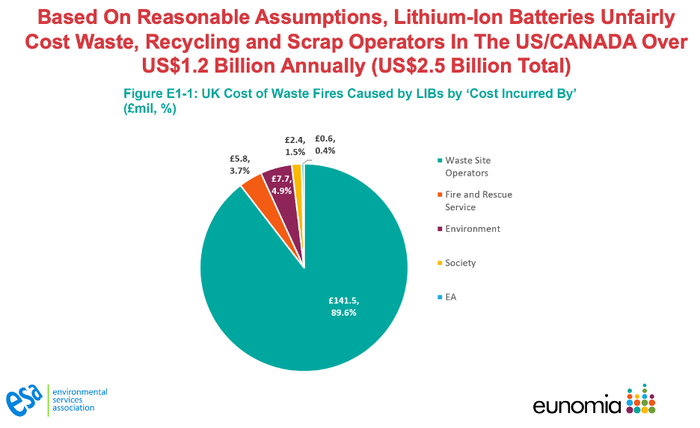

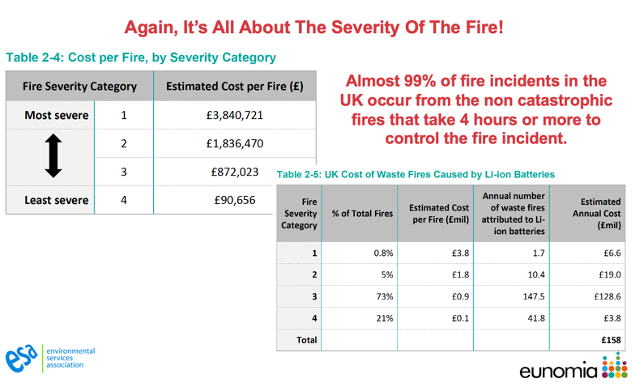

Putting a cost to this in years past has been difficult, but a study completed by Eunomia Research & Consulting for the UK estimated the cost of a fire based on the severity of an incident. Eunomia has estimated the cost of lithium-ion battery fires in the UK to be about 150 million-plus British pounds. If I use my same population assumption for the number of fire incidents, we are looking at the cost of lithium-ion battery fires in the U.S. and Canada to be a staggering US$1.2 billion annually. Add that to the cost of the traditional fire hazards we already are facing and the number doubles to US$2.4 billion annually.

That cost is overwhelming, and it’s unfortunately being borne by our waste and recycling operators, society in general, our environment and the brave fire professionals forced to fight most of these events. I would love to be proven wrong, but I believe that I can safely say that none of this cost is being borne by the manufactures of this technology. The nominal investment they make in non-profits that teach proper recycling might be working, but more needs to be done to keep up with the increasing supply of lithium-ion batteries to come.

In addition to the burden of high costs, waste and recycling operators are faced with another challenge: insurers leaving the occupancy at a fast pace. This issue was brought to my attention a few years ago, and it’s pretty clear that the waste and recycling operator bucket of costs, which makes up the majority of Eunomia’s number, is mostly insurance companies. Insurance companies have been writing high risk hazards for years, but only, and I stress only, when the industry understands and controls that risk.

To bring more awareness to this issue, I wrote an article in Waste360 in August titled, “August 2020 Fire Report: Hey, Insurance Companies! Not So Fast!” In this article, I sat down with Ryan Butler from Cottingham & Butler who explained that wholistically insurance companies are becoming more adverse to their risk profiles. One thing he said really stuck with me: “Too often operators, insurance brokers and consultants in the sector view insurance coverage as the first line of defense.” In reality, your insurance policy is the last line of defense. Today, it falls 100 percent on the operators to ensure they don’t have fires. Let me rephrase that: It is not about the number of fire incidents we have but the severity of the fire incidents we experience! That being said, it’s important to have proper policies and practices in place to deal with fires when they do occur.

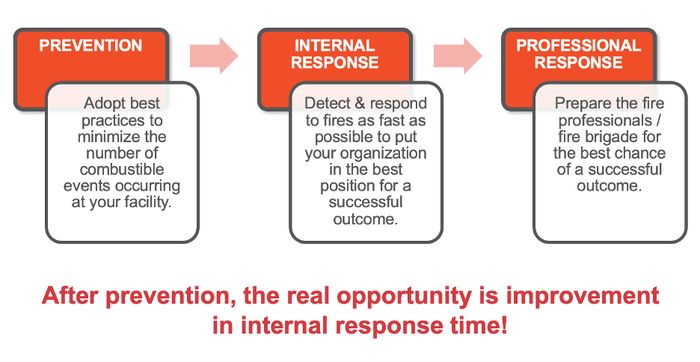

Prevention. The most important part of fire prevention is to develop a plan of attack. Prevention is the basic blocking and tackling and should include all components of minimizing the potential number of events that can occur at your facility. In Appendix F, you will find a proven approach to safely fighting a waste and recycling operation fire. The approach was developed by me and Jim Emerson of Star Risk Technologies and has been published in International Fire Protection Magazine and a number of other education and learning outlets.

Across the pond, the Waste Industry Safety and Health Forum (WISH) aimed for a fire to be extinguished with traditional fire and prevention practices in a four-hour time period.

It is worth noting that WISH didn’t mention a thermal detection in its guidance, but it did provide the following tip:

Tip – thermographic cameras are becoming more economic to purchase and are also becoming more common in use on waste management sites. Such cameras can be used as part of routine inspections to identify electrical faults, over-heating equipment and other potential ignition sources. They can also be used during fire watches after hot works.

The Institute of Scrap Recycling Industries (ISRI) penned a guidance document on how to prepare a fire prevention plan, fight incipient stage fires and be prepared in the event of a crisis management scenario. ISRI did not mention early detection or solutions like our Fire Rover, a comprehensive firefighting solution that combats incipient fires and explosions within seconds from ignition, but these “best practice” documents and training materials are critical to ensure that we as an industry are seen by insurers and first-class operators.

Internal Response. This is key and where the opportunity for improvement in our fire responses is the greatest. I typically tell folks that early detection is the key to catching and mitigating a fire early. The goal is not just to catch a fire when there are flames but to understand that there are situations where hot spots can be cooled before they flame. The goal is to set the trip wire as early in the process as possible. This can be done through top-grade thermal detection in combination with smoke and other analytics and, most importantly, a highly trained agent who is able to weed through false positives in an effort to fight only the incidents that need fighting.

Our Fire Rover solution eliminated 207 fires in 2020 at high hazard areas we protect. We are making a dent in the number of fire incidents that are controlled and mitigated at waste and recycling operations in the U.S. and Canada. If we use Eunomia’s estimates for the cost and severity of fires, we could have decreased costs from $30,000,000 to $248,000,000 in 2020 for our U.S. and Canadian clients, fire professionals, society and the environment.

Our solution of best practices and investments in technology is working. How do we know this is the case? Insurance companies have noticed. In 2018, insurance companies couldn’t leave our occupancy fast enough. Since that time, we have been gradually gaining options for the best operators. I have personally fought and won favorable outcomes by proving that our customers that have developed operational best practices, in combination with having our early thermal detection and fire elimination solution in place, have less fire risk than any point in history, which includes the time before the lithium-ion battery wave even began.

Yes, there is a hard cost to installing and maintaining a Fire Rover system in your operations, as there is with most safety investments, but to more and more insurers, it is a cost of mitigating risk to make it more palatable to underwrite. The bigger question is who should pay for these types of investments?

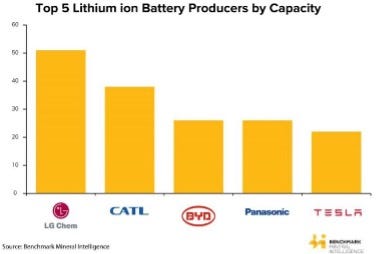

There are five main lithium-ion battery operators in the world (listed above). They are manufacturing a product that we need and that has many positive effects on our lives and society, so I don’t view these companies as evil villains that are trying to deliberately cause harm to the public. It is simply about the allocation of risk, and it is typically our government’s job to help distribute that risk fairly among all of the players in a product’s supply chain.

Currently, our waste and recycling operators are unfairly bearing the brunt of that risk. I believe a good case can be made that the government needs to step in with grants, loans and policies that help educate the public on how to properly recycle their batteries. Additionally, investments in the form of grants, low interest loans, beneficial tax incentives, etc., need to be made in technology to ensure safety on the frontlines.

Professional Response. The other extremely important part of the internal response is to prepare the professional response. Investing in having the proper equipment for the fire department onsite can be a huge timesaver. Even going as far as attached and rollout hoses so the firefighters can immediately start applying suppressant to the affected area can make a huge difference. Most importantly, having an active relationship with your local fire department is imperative.

All of these efforts can help prevent fires, but after six years of putting our patented Fire Rover solution to use in the industry, I can confidentially say that our solution can and is the only solution on the market today that can lower the risk profile of a good operator to levels seen before the lithium-ion hazards hit our industry.

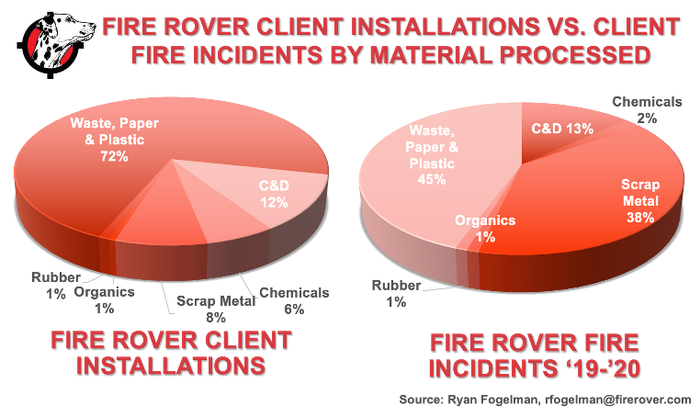

As we look at the results from our approach, the Fire Rover has protected transfers stations, materials recovery facilities (MRFs), construction and demolition (C&D) operations and others. Additionally, clients that have installed our solution in their high hazard areas have been able to secure better rates with insurance companies.

As we continue to share this positive news with insurers across the globe, we are being asked to bring our solution to other countries. Our focus remains on protecting our clients in the U.S. and Canadian industry and getting us back to a healthy insurance level so we can focus on what is most important: keeping our cities clean and sanitary and reusing our materials to lessen the amount going to landfills.

If you would like a full digital or PDF copy of the “2020 Reported Waste & Recycling Facility Fires Annual Report” when it is published, please contact me directly or visit https://share.hsforms.com/1BfbGLhtpQMaVg2Haf73tqg4ljm3

Ryan Fogelman, JD/MBA, is vice president of strategic partnerships for Fire Rover. He is focused on bringing innovative safety solutions to market, and two of his solutions have won the distinguished Edison Innovation Award for Industrial Safety and Consumer Products. He has been compiling and publishing the “Reported Waste & Recycling Facility Fires In The US/CAN” since February 2016 and the “Waste & Recycling Facility Fires Annual Report.” Fogelman speaks regularly on the topic of the scope of fire problems facing the waste and recycling industries, detection solutions, proper fire planning and early-stage fire risk mitigation. Additionally, Fogelman is on the National Fire Protection Association’s Technical Committee for Hazard Materials. (Connect with Ryan on LinkedIn at https://www.linkedin.com/in/ryanjayfogelman or email at [email protected])

About the Author

You May Also Like