Riding the Wave of Liquid Waste Disposal

A recent EREF report wades into how landfills solidify and stabilize aqueous/special waste materials.

Currently, 48 U.S. states allow non-municipal solid waste (MSW) materials to be placed in MSW landfills, including 33 states allowing industrial waste and 27 allowing biosolids and sludge. There has been a trend in recent years to place more non-MSW wastes into landfills and, as a result, facility owners have devised a variety of ways to manage them.

Some example types of these special wastes include:

Brines from industrial processes (e.g. flue gas desulfurization brine from coal power plants)

Oil/gas industry wastes (e.g. mine tailings, drill cuttings/mud, etc.)

Off-spec liquid, gel or similar products (e.g. deicing liquid, petroleum-based products)

Expired or off-spec liquid food wastes (e.g. barbeque sauce, beverages)

High-strength organic wastes or food industry by-products (e.g. animal renderings, fishing industry offal)

Industrial/domestic septage or sludges

Grease trap waste

Contaminated soils/sediments (e.g. dredged/excavated materials)

Note that most of these wastes have a very high moisture content and can be wet solids, paste-like in consistency or liquids. Further, many could contain materials that may be chemically reactive, which could, for example, generate heat. As a result, these waste streams pose unique challenges when managing them at the working face. Successful placement of high moisture content or liquid wastes in a landfill depend on many factors. However, reducing the moisture content is one of the most important since this serves to impart structural stability to the material and minimizes the potential for generating excess liquids at the working face.

Landfill owners have been sensitive to the unique characteristics of special wastes that may require tailored management approaches.

“Where landfills experience diminishing MSW volumes or where we see relative increases in industrial and municipal sludges that are soft and wet wastes, landfill operators need to be mindful of the potential reduction of waste strength characteristics and when necessary stabilize these soft wastes with binding agents to increase waste strength properties prior to disposal,” notes Greg Cekander, vice president of the Environmental Management Group at Waste Management Inc.

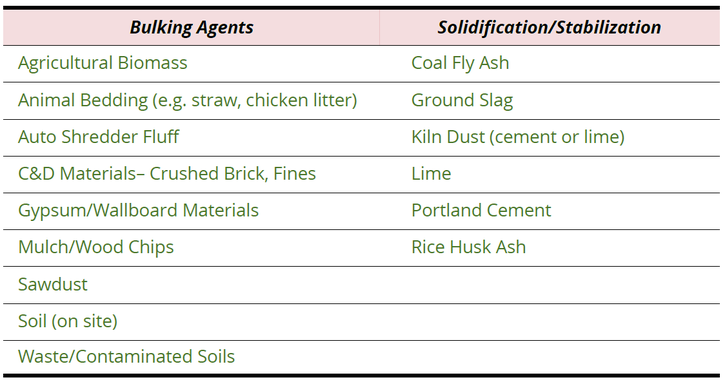

Binding agents used to manage special wastes fall into two broad categories: bulking agents and solidification/stabilization (S/S) agents.

Bulking agents primarily serve to reduce moisture content of the waste material and work through physical absorption of moisture. Common examples of bulking agents include things like sawdust, mulch and soil. Industry interviews have suggested that unusual absorptive wastes (e.g. off-spec baby diapers) have been used as bulking agents when available. While bulking agents absorb water, they do not generally provide structural integrity or control contaminants in wastes.

S/S agents, on the other hand, possess properties to encapsulate the waste through chemical reaction. Common examples of S/S agents include Portland cement, lime and fly ash—materials that harden to provide structural integrity and can minimize leaching of contaminants like heavy metals. Although reducing moisture is the primary reason for S/S, other applications include:

Ensuring acceptable structural stability when placing wastes in the landfill

Reducing biological oxygen demand concentration to ensure landfill microbial health

Minimizing odor potential

Reducing exposure to workers where there is a potential safety hazard

Minimizing leaching potential for certain chemicals, heavy metals and toxic compounds

Information on the use of bulking and stabilization practices has not been widely available. The Environmental Research & Education Foundation (EREF) recently conducted a thorough review, which identified 15 common agents used for the bulking and S/S of special wastes. Given the wide variety of bulking and S/S agents available and their potential for reactivity, care must be taken when operators evaluate whether to accept liquid wastes and how best to manage them onsite. Considerations include bench and/or pilot testing before accepting new wastes, processing area design and placement within landfill cells to avoid concentrated areas or those near final slopes.

With the acceptance of aqueous wastes on the rise, refining and developing more mechanistic approaches to aid in the selection of appropriate agents may improve the current state of practice. To this aim, EREF’s recent free report details the characteristics of bulking and S/S agents; investigates the pros and cons of specific agents; and reviews important operational considerations such as mixing ratios, heat generation, structural stability and leachability.

About the Authors

You May Also Like