Could Lifecycle Models Impact Big Change?

Lifecycle models could continue to disrupt the industry as they become more commonplace.

A lifecycle model, adapted from a model that primarily researchers use to evaluate solid waste practices, is rolling out to the public. The U.S. Environmental Protection Agency (EPA) is releasing a user-friendly version that’s free to local and state governments and others—even though lifecycle thinking challenges how the agency has encouraged them to manage their trash.

As lifecycle models and tools become more commonplace, they could continue to disrupt the industry, as well as how goods producers operate.

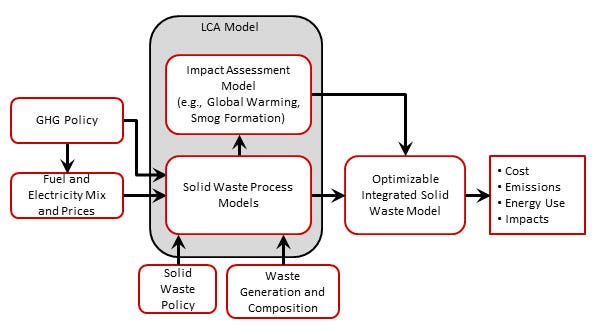

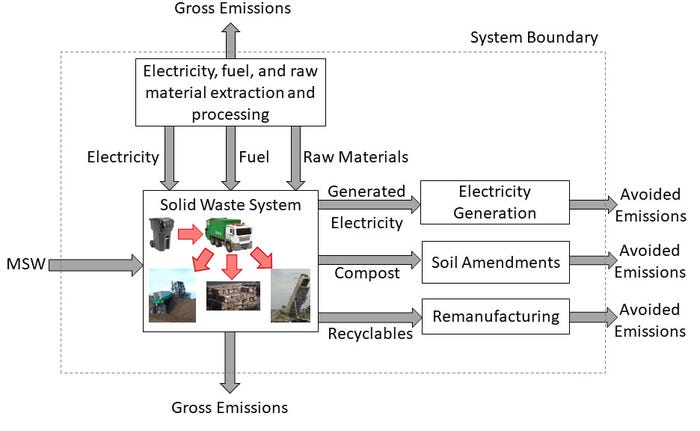

Solid Waste Optimization Life-cycle Framework (SWOLF), which the public version is based on, looks at processes from waste collection, separation, landfilling, combustion, anaerobic digestion and composting. And it quantifies materials, energy consumption and emissions associated with these processes.

“The whole notion of thinking from a lifecycle perspective forces you to look at every aspect of each process and assess it comprehensively,” says Mort Barlaz, head of North Carolina State University’s Department of Civil, Construction, and Environmental Engineering, which developed SWOLF. “For example, there’s an assumption biodegradable cups are better than polystyrene, but for the average landfill, biodegradable materials do more harm than good from a greenhouse gas emission perspective. It’s assumed these materials degrade fast, saving space and making methane to recover. But landfill owners don’t install gas collection systems for at least one or two years from time waste is buried. So, if it degrades prior, you just emitted methane into the environment. With polystyrene, there would be no greenhouse gas emissions.”

The idea is to help make decisions and understand environmental and economic tradeoffs, while considering future changes in what waste management systems will look like, explains Jim Levis, a research assistant professor at North Carolina State University, who worked with Barlaz on SWOLF.

“We aren’t just taking a snapshot of where we are now. But if we build a material recovery facility or waste-to-energy plant, how well will it perform in 30 years with different waste, different systems and different policies?” says Levis.

Municipalities can customize data.

“Every community is struggling with resources, and lifecycle is enabling them to make the best decisions and the best use of those resources based on what’s an important issue in their region,” says Susan Thorneloe, research environmental engineer for EPA.

Industry is also beginning to have a look through this different lens. Procter & Gamble was the first, using it to identify sustainable manufacturing practices like lighter containers and smaller packaging to minimize burden at the end of life.

Lifecycle thinking is slowly permeating the supply chain, potentially impacting players beyond those in a few silos.

“If a large retail chain would decide to only buy products with a certain carbon footprint, or buy only from manufacturers who proved their products were made with minimal emissions and energy, they could shift the market. This could force manufacturers to adopt certain practices. And lifecycle could be a tool to quantify,” says Barlaz.

While these models can help make better decisions, they have to fight preconceived notions on how solid waste is managed, says Jeremy O’Brien, director of the Solid Waste Assocation of North America’s (SWANA) Applied Research Foundation.

For example, the EPA's Food Recovery Hierarchy may not apply to every community, according to a SWANA report. The report presented a scenario looking at mixed food and yard waste, where combustion at a waste-to-energy plant or landfilling might yield higher emission reductions than composting.

“So, in this case, the preconceived notion in question is the prevailing perspective that the Food Recovery Hierarchy applies to every community. Meanwhile, lifecycle studies consider local data and conditions to identify the most effective approach, from an emissions reduction standpoint,” says O’Brien.

Some governments are now changing policies and practices through assessment takeaways.

Concerned about quickly depleting rare earth elements, Sweden has done lifecycle analyses to determine how to build electronics and vehicles to more efficiently recover these metals.

Domestically, change is happening too.

“Seattle was looking at increasing its recycling rate but didn’t realize how they collected was aggravating smog. With what they learned, they started looking at better collection models to reduce emissions. So now, they aren’t just looking at recycling rates. They are looking more holistically. If you look in isolation, it may cause other problems,” says Thorneloe.

About the Author

You May Also Like