How Samsung is Tackling the Global E-waste Problem

Mark Newton, director of corporate environmental affairs at Samsung, discusses the company’s e-waste reduction goals and milestones.

Electronic waste (e-waste) is a fast-growing segment of the world’s waste stream, and as companies release new and improved products, consumers and businesses are quick to part with their old devices and invest in the new.

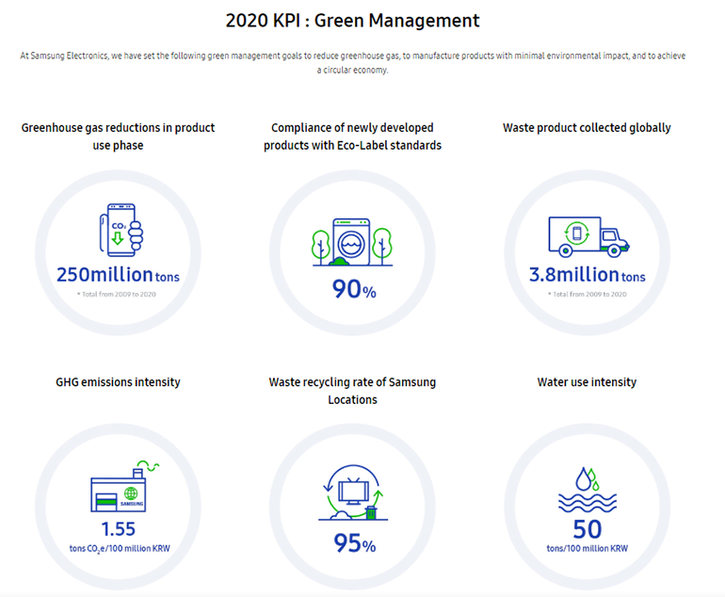

In an effort to collect and recycle or reuse those products in a responsible manner, multinational electronics and information technology company Samsung is continuing to expand upon its e-waste reduction programs, which are available to both businesses and consumers. The company also is setting sustainability goals to reduce greenhouse gas emissions and water usage, as well as recover more recycled materials.

Waste360 recently spoke with Mark Newton, director of corporate environmental affairs at Samsung, about the company’s mission to reduce e-waste, some of its e-waste reduction goals and milestones and how it’s developing more sustainable and recyclable products.

Waste360: Discuss Samsung��’s mission to reduce e-waste.

Mark Newton: Samsung responsibly collects and recycles old, unwanted or nonworking electronic products in the U.S., and we have programs in place to manage the recycling needs of our business partners. The reason for doing that is twofold: First, it’s to provide a service for our customers (no matter where they are located in the U.S.), so they have an easy way to responsibly recycle their products. Second, it’s to abide by our commitment to responsible recycling.

While the U.S. is not a party to the U.N. Basel Convention, Samsung, through its global policy and fulfillment in the U.S., is working through partners that subscribe to a high standard that would restrict the export of nonworking electronics and hazardous waste to developing countries. By doing that, we can offer an additional level of security to our customers about the materials we are handling on their behalf.

We have collection and recycling services for businesses and can refer our business partners to companies that specialize in different areas. For late-model equipment that has value, for example, businesses can work with our partners to refurbish that equipment through what we call a value recovery program. Through the program, our partners will collect the equipment, ensure all data security considerations are taken care of and ensure the material is responsibly recycled, refurbished, resold and remarketed. Oftentimes, there’s value left in the products that can help offset the cost of recycling or remarketing and can even go toward the purchase of new equipment.

We also have collection and recycling services for consumers. Most of the products that end up in the consumer waste stream are older, so the material we collect either through retail partners or municipal collection sites tends to be between five and 10 years old and has limited value. For the materials that do have value, we try to recover what we can and implement the higher order principals for sustainable materials management (SMM). If we can keep the material in commerce, it’s a much better environmental result than if they were just simply ground up and recovered for base or precious metals.

For consumers, we also have trade-in programs that we run from time to time to take functional products off consumers’ hands and help them replace those products with ones that may be more environmentally responsible and energy efficient.

Waste360: When did Samsung start collecting and recycling e-waste, and how have its recycling programs evolved over the years?

Mark Newton: We started in the early 2000s, when regulations driving electronic recycling programs in Europe started to spread to the U.S. But ahead of that, Samsung started recycling programs voluntarily, helping to reduce e-waste.

Over the years, legislation has expanded here in the U.S., though we don’t have a national legislation that requires e-waste collection or recycling. To date, 25 states and Washington, D.C., have different laws with respect to which products should be recovered and the mechanism for doing that.

Additionally, there are a number of standards out there to help govern responsible behavior, such as the e-Stewards Standard, which has set the bar high for responsible reuse and recycling and ensures that e-waste is handled properly. I am proud to say we have been certified to the standard, and we continuously stay active with the development of the standard as it evolves.

Waste360: In 2017, Samsung collected and recycled more than 124 million pounds of e-waste. Tell us about that milestone.

Mark Newton: We’ve been collecting material and keeping track of our metrics for over a decade. We collect and recycle 100 million pounds of e-waste per year in the U.S., and if you look at the amount of material we’ve collected in the U.S., we’re on target to collect more than one billion pounds of electronics since 2008.

Globally, through 2017, we collected about 6.2 billion pounds of electronics and responsibly recycled that material. We are now on track to collect and recycle about 8 billion pounds of electronics globally by 2020, and we have a goal to collect and recycle 15 billion pounds of electronics globally by 2030.

In addition to the e-waste goal, we’ve set a goal to recover one billion pounds of recycled materials including plastic by 2030. Paper is also a big part of the material that ends up in our products, and we use it to ship materials and make our literature, so we set a goal to ensure that 100 percent of the paper used by Samsung is responsibly sourced and conforms to the international standards for responsible paper sourcing and the Forest Stewardship Council.

These important goals complement the milestone of 124 million pounds of e-waste collected and recycled in 2017.

Waste360: Samsung recently received the Environmental Protection Agency’s (EPA) Sustainable Materials Management Gold Tier Champion Award and was recognized by the EPA for its sustainably designed products and processes, as well as diverting nearly 276,000 tons of e-waste from landfills. Tell us about that.

Mark Newton: We have a deep, long-standing relationship with the EPA, and we are a big supporter of their environmental programs. The SSM program that we were recognized for is essentially given to companies that have set and exceeded goals in respect to the responsible collection of electronics. There are now 11 companies in that program that have collectively diverted 276,000 tons of electronics from landfills, which is significant.

Taking a lifestyle approach to the way we design our products is what the SMM idea is all about, and it’s the core of the EPA’s program. We are taking steps in the development and manufacturing of our products and helping to ensure our customers are using our products in a more environmentally responsible way. One of the ways we are doing that is through repair and reuse. Another way is via our takeback and recycling programs.

In addition to SMM and our recent recognition, we’re heavily engaged with the EPA’s ENERGY STAR program, which is focused on energy efficiency. Most of our products are ENERGY STAR certified, and we think it’s an important aspect given the fact that we’re an electronics company.

We also participate in EPA’s Green Power Partnership, which encourages organizations to use green power. We recently made a global commitment to source renewable power for all our electricity use in the U.S., Canada and Europe by 2020, and we’ve already met that goal in the U.S. this year.

Lastly, we partner with the EPA on building efficiency to drive energy efficiency across our footprint from a facility standpoint.

Waste360: As you know, electronic products are designed with many different types of material, some of which are hard to break down and recycle. Can you talk about how Samsung is working to create more sustainable and recyclable products?

Mark Newton: We try to recover as much functionality out of the product as possible, but when it comes to materials, especially sensitive materials that may be present, like mercury, we take the necessary precaution to make sure they are segregated.

Materials that cannot be repurposed, reused or harvested for functional parts are typically shredded and end up in different fractions—there often is a ferrous/magnetic metals fraction, a non-ferrous/precious metals fraction, a plastics fraction and another fraction for cables and similar materials. Those fractions are then handled by downstream partners that specialize in processing those materials.

We also take data security very seriously. We advise our customers to scrub their data from their products before they are placed into the waste stream, and we take additional precaution through our partnership and performance in e-Stewards certification to ensure that data is properly destroyed.

Through all of these measures, we are trying to drive the highest level of recycling that we possibly can once we get past the ability to reuse or refurbish a product. One of our goals is to actually drive a 95 percent recycling rate by weight of all the products that get recovered through our system. We set that goal several years ago to meet by 2020, and we actually exceeded that goal by 2016. What that means is less than 5 percent of the materials that come through our waste stream cannot be recovered and have to be incinerated or landfilled according to statute.

We have done lifecycle assessments and material assessments for all our product categories, so we know how much material and which types of materials are in our products. A typical cell phone, for example, is made up of about 35 percent plastic and 65 percent other materials like aluminum. And the batteries used in many of our products contain cobalt, which is a limited resource that can be recovered.

Ultimately, we want to keep these products in service through our Samsung authorized network, and recently, we partnered with uBreakiFix, which has expanded our walk-in, same-day repair capacity to over 300 locations in the U.S. We also have a number of retail partners, including Best Buy, that work with us to make it as easy as possible for customers to keep their products in service.

Waste360: Can you talk about Samsung’s partnerships with recycling companies and how those partnerships are helping combat the issue of e-waste?

Mark Newton: We partner with other manufacturers through the EPA programs we are involved in, and we also have partnerships through our compliance programs. We’re extremely selective in terms of which recyclers we will actually partner with. We look for companies that have the experience and capacity to safely and securely handle the amount of material we’ve processed through our network, and we try to avoid any partnerships where electronics are exported to developing countries that don’t have the social or environmental framework in place to properly repair these items.

We’re very transparent about who are partners are, and we list that information on our website along with information about our policies around recycling, product design, etc. Our goal is to design with clean materials so that when products are recovered, the materials can be recycled via our partners and brought back into commerce.

About the Author

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)