Contelligent’s Woodward Discusses Automated Containers/Smart Technology

Contelligent, formerly OnePlus Systems, sells intelligent container monitoring and analytics solutions to waste companies and other industries. Keith Woodward, executive vice president of Marketing for Contelligent, talked to Waste360 about the offerings of the global, 30-year operation.

Woodward also takes a deeper dive into considerations that must be realized to develop technology tailored specifically for the waste industry. He projects future direction of intelligent technology in waste management, and he shares what he thinks will drive that direction.

Waste360: Can you briefly describe each of your main products?

Keith Woodward: Contelligent provides intelligent monitoring and analytics solutions for numerous container types and applications that include both IoT sensors and our patented cloud-based software. We provide two types of sensors; one is designed for compactors and is generally for municipal solid waste and recycling.

The other sensor type is used to monitor fill levels across a variety of closed top containers used for a variety of applications, such as is used by companies that distribute fresh oil and lubricants, or is used for collection of materials such as clothing donations, textiles, and used cooking oil.

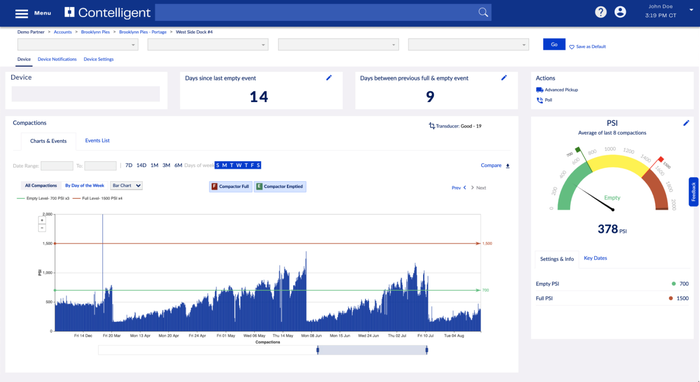

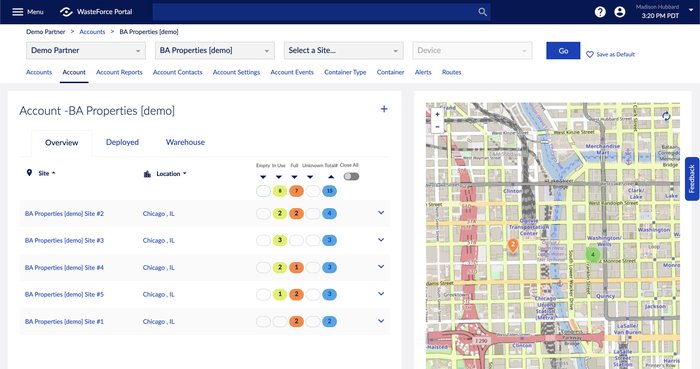

Our IoT sensors communicate directly with our cloud-based software platform that provides users visibility and control in real-time on the fill status of their containers.

Waste360: What exactly is sensor and cellular technology? How do they work together?

Keith Woodward: Sensors are physical devices designed to collect and send information to our cloud software solution where it is converted into actionable insights relating to container fullness. The sensors communicate using cellular technology. Cellular technology is proven to be far more reliable, much easier to use, and provides far better security than wireless.

Our sensors can be easily deployed to start collecting information on a compactor. Data is captured and sent to a cloud software platform that will apply sophisticated and patented algorithms to translate the data into accurate fullness information for any compactor.

When fullness levels are reached, the system notifies the hauling company for pick up. Intelligent monitoring technology automates the waste operation and virtually eliminates the need for using labor for manual tasks. Hauling companies have visibility and control of their waste operations and can use data to increase operational efficiency and to improve their service reliability.

Waste360: From an operational perspective, what does the compactor monitor enable haulers to do that they couldn’t do before?

Keith Woodward: It provides greater transparency and control. Using robust sensors and cloud software, the solution will locate containers and compactors and alert operators to the fullness status of any compactor or container anywhere, when before they did not have this visibility. This allows them to assign routes based on fullness level and location.

Monitors enable haulers to align drivers more efficiently than they could before, and to the right locations for pick up, as well as help avoid the historical problems relating to untimely pickups. Monitors also help optimize tonnage per pickup, so they are doing less back and forth hauls.

And hauling companies have one more tool at their disposal for addressing ongoing challenges around growing shortages in skilled labor because it helps them acquire more customers without having to increase their local fleet size. The technology accomplishes all these things while removing the need to intervene manually.

Waste360: What are specific considerations in the waste industry that must be realized to develop well-suited intelligent technology in this niche?

Keith Woodward: First, intelligent waste monitoring technology must be scalable, flexible, and capable of adapting to changing conditions, regulatory situations, harsh environmental conditions, and must possess the ability to monitor unpredictable, variable volumes of waste and recycling. It also must demonstrate the ability to accurately provide information contained from within those containers.

It’s no secret; the waste industry has been relatively slow to adopt technology. However, as industries prepare for a post-pandemic world, we see more hauling companies starting to rethink and retool parts of their operation with technology to become more efficient. If they’re not using technology to drive operational improvements, they will find it challenging to compete in the future.

Waste360: Where do you see the future going for intelligent technology in waste management? What will drive this direction?

Keith Woodward: I see the already growing demand for intelligent waste monitoring technology continuing to grow. This trend will largely be driven by increasing demands from the waste generator, increasing market competition, and a widening gap with skilled labor.

Waste360: What problems and challenges still need to be addressed for intelligent technology to continue advancing?

Keith Woodward: The technology is mature enough to support market growth. Preventing further adoption really comes down to market education. We conducted a survey at the end of 2019 and asked the respondents: “What prevents you from using smart waste monitoring solutions?” Forty-two percent said they were simply not aware that these tools existed, and another 25 percent said they needed help educating senior executives.

The advent of intelligent waste monitoring technology can provide a pathway for future innovation across the market. It simply requires more market education.

Waste360: How do you see the technology continue to evolve, industrywide?

Keith Woodward: With population growth, and thus growth in waste generation, the pervasive thinking around waste management needs to be reimagined. Advancing technology provides a pathway to do just that and will continue to move in that direction.

Intelligent monitoring technology will become a standard way for managing how and when compactors or containers are picked up and returned. And as adoption continues to increase, providers like Contelligent can develop benchmarks as they relate to industry segments, regions, and more. This will provide the benefit of enabling users to learn how they can further improve the efficiency of their operation.

Further, we continue to experience stronger partnerships with hauling companies who see smart/intelligent technology as strategic to their operation.

Waste360: What advice do you have for waste management companies shopping for automated/intelligent technology?

Keith Woodward: As mentioned earlier, intelligent waste monitoring technology solutions will improve operational efficiency and can provide them with a competitive advantage in their markets. In selecting the right vendor, hauling companies should evaluate the flexibility of the solution as well as its accuracy and ability to scale and present information that is easy to consume and is actionable.

Further, waste companies need to assess the support infrastructure of the solutions provider. As an example, we provide support through a customer success function that includes teams of dedicated experts to onboard, train, and provide customers another set of eyes to help monitor their fleet, giving customers confidence their waste and recycling operations are running efficiently.

About the Author

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)