ReFED Supports Innovators in De-Risking and Scaling Food Waste Solutions - Part 2

Nonprofit ReFED established a Catalytic Grand Fund to support innovators working to turn the tide on this swelling waste problem, seeing that good food gets put to use. In this two-part series you will learn how the grant works, what it and its recipients are accomplishing, and with funding from who. Part 2 tells a recipient’s story, coming straight from the ambitious startup’s CEO and founder, Eric Weaver.

June 15, 2023

About 38 percent of the 241 million tons of the U.S. food supply went unsold or uneaten in 2021, most which wound up on landfills, got burned, or left to rot in fields— carrying heavy financial and environmental costs. Nonprofit ReFED established a Catalytic Grand Fund to support innovators working to turn the tide on this swelling waste problem, seeing that good food gets put to use.

In this two-part series you will learn how the grant works, what it and its recipients are accomplishing, and with funding from who. Part 2 tells a recipient’s story, coming straight from the ambitious startup’s CEO and founder, Eric Weaver.

Waste360: Tell us about how Transparent Path’s technologies work

Weaver: We provide advanced hardware and software to create visibility into supply chains, especially for perishable goods. This includes cellular trackers that are placed within shipping containers to track the GPS location, temperature, humidity, etc.

We also develop software and predictive algorithms to help make sense of that data. This data allows the sellers of perishables — producers and processors — to make agile decisions about shipments before and while they are enroute to their customers. The data also allows the buyers of perishables — grocery chains, food service companies, restaurants — to know when shipments will arrive, and what condition the products will be in. And we’re developing an app to provide consumers with information about their food purchases, so they can make more informed decisions about shopping and consumption.

Waste360: What problems around food waste do most existing technologies miss?

Waste360: What problems around food waste do most existing technologies miss?

We’re so used to Amazon texting us that our package is “five stops away.” But when it comes to the distribution of perishables like food, we’re still largely dealing with faxes, paper, phone calls, and emails. The lack of digitization means we never find out a container of food has been compromised until after it reaches its destination. That creates a tremendous amount of food waste. Large retailers have told us they reject between 10 to 14% of their purchased perishables. For Walmart alone, that would equal $31B— container after container— going into landfills. Now add Kroger, Safeway, Whole Foods, etc., and you can begin to anticipate the size of the problem.

Waste360: Do you have a story that really makes tangible the impact of food left to waste?

Weaver: Let’s consider a true story of a large container of king crab, left sitting at room temperature on a receiving dock for a week due to a clerical error. It’s not just $400,000 in crab meat wasted; it’s the diesel for the fishing boat to get out to the right spot in the ocean. It’s the wasted salaries. It’s the wasted electricity and oil and fresh water, pumped from dwindling aquifers, to process the crab. It’s the wasted diesel to truck it to stores. And it’s the methane that waste will produce in landfills. Add it up and it’s over $1M due to one simple mistake — along with a huge impact to the environment.

Waste360: How does your technology prevent disruptions like what you just described?

Weaver: Going back to our connected, cellular sensors: they constantly transmit location, temperature, humidity, etc. from inside the container, and our system sends out a real-time alert when something goes sideways. That allows a driver or a warehouse crew to intervene and save the shipment.

All of that rich data allows us to provide everyone — food sellers, buyers, and consumers — with more information than they’ve had before. The producers and grocery chains can be more efficient, waste less money or time, and reduce significant losses and food waste. We call this our Transparent Path Visibility Platform – it’s in market, and we have customers in seafood, fruit, produce, and sauces.

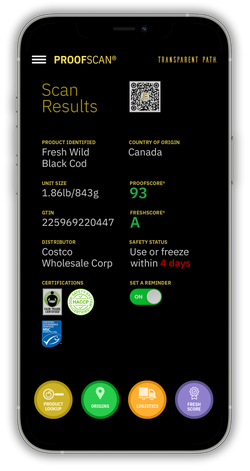

Now, by enabling some of that data to be accessible to consumers, via our ProofScan mobile app, consumers can make better decisions about what they purchase and how they consume it.

Waste360: What are consumers telling you they want to know about the food they buy?

Weaver: We conducted a consumer research study a few years ago that showed that trust is in short supply, and consumers want more information about the food they feed their families. Fifty-five percent were willing to pay more to have access to this information. Through the app, we can provide data about the origin of food products, certifications, and even how the food got to them.

Waste360: How are you applying artificial intelligence (AI) to food?

Weaver: We’ve developed and patented a freshness prediction algorithm called FreshScore. Think of it as a “credit score for freshness.” We look at production data, harvest dates, packaging dates, sell-by/best-by dates, etc. We use that data to predict a freshness score. We can anticipate how fresh something will be long before it arrives at the grocery store. By placing that FreshScore on the packaging, both grocers and consumers can look up today’s freshness level. That’s a gamechanger for decision-making across the entire food industry.

Waste360: What have been your biggest challenges in growing a successful business leveraging data to prevent food waste?

Weaver: We launched the company right as the pandemic was taking off. That really made the work extra challenging: harder to meet as a team, harder to develop the platform, and harder to pitch to new customers who were worried we might bring the virus into their workplaces. These days, we’re selling to folks who have information overload, distrust of new technologies like blockchain or AI and, to a certain extent, apathy.

It’s hard to introduce change, even when it’s a financial no-brainer, when so many people have hit max load on their resilience. The food industry is also, generally, older, with more people near retirement. The last thing they want to do is rock the boat with a new type of tech.

Waste360: Who are some of your partners and how did you get them to join you?

Weaver: Fortunately, we’ve had amazing partners and investors who believe in what we’re doing. Intel and T-Mobile were there with us right from the beginning because they wanted to make an impact beyond simple tech products. Our angel and crowdfunding investors feel very strongly about minimizing environmental impact; many of them have stated that they hate wasting food and wanted to do something about it. These folks have allowed us to build out our visibility platform and develop FreshScore. They believe in the team, the mission, and our timing.

And of course the ReFED catalytic grant for $137M was a huge shot in the arm. It shows us that others share our vision.

Waste360: Where are you finding most interest in your technology and why?

Weaver: We’ve found quite a bit of interest, particularly overseas. Outside the U.S., customers express huge concerns around food insecurity, climate change, and environmental impact. Environmental impact, and the carbon reporting we can provide, is hugely important in Europe.

In Central Asia, customers are telling us that cold chain breaks are resulting in 30 to 40% of shipments compromised. And in South America, we’re hearing that a lack of cold chain continuity is a strong reason for needing technologies like ours — to prove something was safely shipped.

Waste360: What’s this new venture you’re moving into to create compostable products?

Weaver: We’re doing this with a grant from the National Science Foundation. It’s to create sensors that are biodegradable — and eventually, compostable. Imagine — compostable electronics! We will be able to print sensors (and their batteries, SIM cards, etc.) out of biodegradable materials that won’t create e-waste. We’re working with Duke University on that project.

*This article was edited for length.

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)