NERC Conference Highlights the State and Future of Northeast MRFs

Here is a roundup of some key takeaways from day one of the Northeast Recycling Council’s 2018 Conference.

Recyclables are the single largest export commodity from the United States by weight and by volume, noted Susan Robinson, federal public affairs director and director of public sector services at Waste Management. To put that in context, recycled exports are bigger than agriculture, bigger than timber, bigger than automobiles and bigger than food.

Robinson pointed this out during a keynote panel, “The State & Future of Northeast MRFs,” at the Northeast Recycling Council’s (NERC) 2018 Conference in Rocky Hill, Conn., on October 30. Panelists discussed what has been going on one year into China’s National Sword, as well as the challenges materials recovery facilities (MRFs) across the country are facing.

“I think all MRFs need to get together and form a support group,” Robinson quipped. “There are limits to what we can expect [from our MRFs]. I think we ask a lot of our MRFs. We are all investing in technology. There is a lot that a MRF is designed to do, but, unfortunately, there is a limit.”

Robinson was joined by fellow panelists Bob Cappadona, vice president of Casella Recycling, and Frank Chimera, area senior manager of municipal sales for Republic Services. Industry veteran and NERC board member Chaz Miller facilitated the discussion.

All three panelists agreed that contamination and the quality of materials processed at MRFs remained a top priority and would continue to be moving forward. They also pointed to various technologies that their facilities have invested in to improve labor demands, operations and the quality of the inbound stream.

“We’ve done it all,” explained Cappadona. “We’ve added labor. Some folks talk about slowing down the lines. We kind of look at it as processing at the design throughput. Every system has a design throughput, and if you go above a 20- or 25-ton throughput, you risk quality. If you push it, you’ll find little pieces of plastic in the fiber.”

Cappadona also pointed out that slowing down the lines has created some capacity issues, and slower lines mean tons of materials are left without a home. He added that plastic bags are listed as a top contaminant because they continue getting caught in the old corrugated cardboard (OCC) screens.

And then there’s the issue of lithium-ion batteries, which end up dispersed across the inbound stream. “With lithium batteries, it seems like it’s every other week that we have a smoldering item on our tip floor,” he stressed. “It’s really amazing how that has accelerated over the last few years.”

Chimera explained that one of the most significant changes Republic has seen is the types of plastics coming in.

“The biggest thing we’ve seen is the change in water bottles,” he said. “Over the last few years, water bottles have been getting a lot lighter and a lot thinner. It used to take only 48,000 plastic bottles to make a ton. Today, it takes 92,000 plastic bottles to make a ton. So, that is twice the work in collection and twice the work in processing just to get the same output in one ton. And, unfortunately, that one ton of plastic is not valued at what it used to be. The water bottle is really a great proxy for understanding the economics of recycling.”

In addition, MRFs were initially designed to process newspaper, cardboard, mixed paper, cans and bottles. But since the Amazon effect and the demise of various community newspapers, things have changed.

“We have about 10 percent less demand for mixed paper today in the U.S.—both exports and domestics—yet, we are picking it up at the curb every single day,” explained Robinson. “That inelasticity creates a burden at MRFs. Glass is another problem. Again, whether there is demand for it or not, we are picking it up at the curb every single day.”

Robinson noted that Waste Management sees a contamination rate of about 25 percent of everything coming into its facilities right now.

“I think about 20 years ago, we operated about 5 percent contamination—even out of single stream,” she said. “The complexity of the material coming in was very simple; it was newspaper and mixed paper.”

“We are expecting MRFs to solve a lot of problems,” added Robinson. “Given what they are designed to do, I think they are doing pretty well, but we are asking them to basically work magic with a complex stream coming in.”

Robinson, Cappadona and Chimera all agreed on the concept of rewriting the idea of recycling, meaning rethinking what we recycle, how we recycle and when we recycle. All three companies have conducted residential waste audits and used route-based target marketing campaigns to improve public education.

During Q&A, Miller asked all three panelists if they anticipate a return to dual stream recycling. All three agreed though there would be a better-quality product coming out of dual stream, but there are other problems associated with returning to dual stream.

Panelists pointed to the industry-wide labor shortage and aging workforce. They also suggested many residents have become accustomed to the convenience of their wheeled recycling carts. And they questioned the quality of the material coming in and whether it would be worth it fiscally from a hauling standpoint and processing perspective.

In addition to the keynote discussion, there were various informative panels and speakers at NERC’s Conference. Here are some additional highlights from the event:

Challenging Economics and MRFs of the Future

During a panel on MRF trends and contracting, Eileen Berenyi, president of Governmental Advisory Associates (GAA); Michael Timpane, principal and vice president of process optimization and material recovery for Resource Recycling Systems; and Mitch Kessler, principal at Kessler Consulting, further discussed the challenging economics MRFs are facing, as well as what the future MRF will look like.

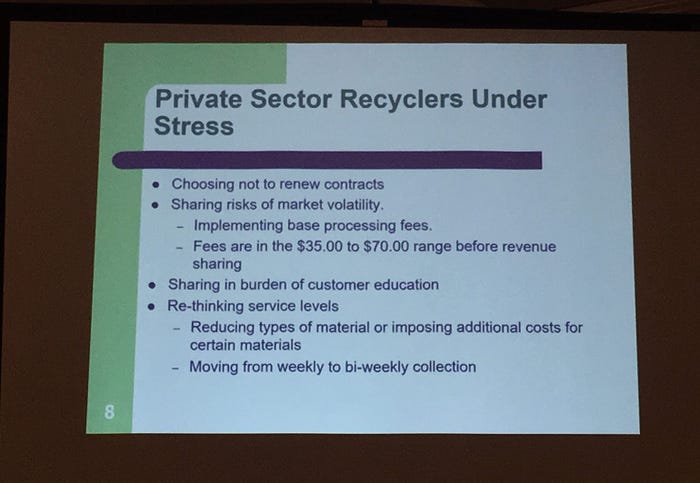

Berenyi explained that while most of MRFs are owned and operated by the private sector, they are under stress. She added that the imposition of tariffs is adding a complicating factor in terms of equipment pricing. Plus, the industry is experiencing transportation pressures.

“Trucking price increases have occurred due to the driver shortage, meaning there is a shortage in the transportation sector itself, not just in garbage hauling,” she explained.

Berenyi also pointed out that technology is becoming more and more sophisticated in terms of sorting, and that includes robotics, optical sorting, ballistic separators, etc. “The technology is supporting separation at the curb, but it still requires manual labor to get materials to the necessary quality. And it’s increasing sorting costs at a time that the market environment is difficult,” she explained.

As for the characteristics of the MRF of the future, Robinson noted the organic proportion of the waste and the amount of food waste facilities take in is going to have an impact on what the MRF looks like. Facilities will get larger—with more capabilities of hosting robotics and technologies.

Timpane stressed the importance of not confusing the public when it comes to recycling. He discussed some best practices that could be implemented, including:

Quarterly face-to-face interactions with the public.

Clear inbound and outbound specifications at all times (be explicit and be detailed).

Auditing is important; know how the stream is changing.

Strengthen force majeure.

MRFs have the right to reject and refuse services. Processors are rejecting loads because there is too much garbage on it that is hazardous to the MRF.

Leverage best practices when it comes to pricing.

In addition, Kessler provided 10 steps to better partnerships and contracts:

All Waste is Local. “Local government is all that matters. When we get into trouble with contracting, it’s the notion that we can borrow someone else’s contract,” he explained.

All Services Have a Cost. The number one failure in the industry has been the failure to communicate the cost of services.

All MRFs are Not Equal.

Recovered Materials are Commodities. “We should never budget for revenue for recycling—that’s another industry failure,” he stressed.

See Different Perspectives.

Controllable and Uncontrollable. “What we really need to talk about are the solutions to things, not the uncontrollable events,” he said. He also referred to China’s import ban as “a long-term gift because we will have better MRFs and material” in the end.

Anticipate Change.

Transparency. “Our industry stinks at transparency, we do not communicate in a clear and open way when things are going down. Full transparency is a rare gift; it’s challenging to provide and it’s hard to find,” he said.

Education and Outreach. “The problem is not up to the consumers to fix. People want to recycle. Our job is to help them do that in a noncomplicated way,” he emphasized.

Customer Service. He stressed the importance of listening to customers’ needs because when customers constantly hear, “No,” it’s not a sustainable business practice.

Fire Prevention and Safety at MRFs

Todd Ellis, Northeast account manager for Call2Recycle, explained during Tuesday’s final panel that the biggest issue facing lithium batteries in the recycling stream is the safe handling of used batteries. And when they are not properly handled, fires happen. That problem, he said, has been magnified in the last several years with the introduction of lithium batteries.

Recovering batteries isn’t easy, he pointed out, so Call2Recycle has developed two campaigns to help: Charge Up Safety and Avoid the Spark. He added that when batteries are being recycled, the terminals need to be protected by placing a piece of tape over the positive charge of the battery. He also stressed that damaged, defective or recalled batteries should not be placed in the normal recycling stream; they must be kept separate.

In order to better manage batteries at MRFs, Ellis noted facilities should contract with a recycler, train employees and develop standard operating procedures.

Ryan Fogelman, vice president of national accounts for Fire Rover, explained that there have been 366 fire incidents that happened in waste and recycling facilities in the last year. Year-to-date, fires have increased 37 percent, and 50 percent of fires are caused by lithium-ion batteries.

Fogelman also noted that Fire Rover has seen a lot more scrap metal fires. And while the industry has focused on preventing fires, he said, facilities don’t focus on the first 10 minutes, which is critical when it comes to containing the event. He stressed that facilities must develop a fire safety plan and to ensure all employees are trained—even if it means bringing in a local fire department to help. At the end of the day, he noted, it is a combinational approach of people, processes and technology.

About the Author

You May Also Like