Brightmark to Build Chemical Recycling Plant in Thomaston, Georgia

Brightmark calls its technology “plastics renewal,” which it bought from RES Polyflow who developed it to convert plastics to fuel. Bob Powell, Brightmark founder and CEO, says his team finetuned it to be able to make new plastic products from plastic waste (considered a higher-value use than fuel). He says it can process plastic nos. 1 through 7—even if they are mixed with food, paper, dirt, or other contaminants.

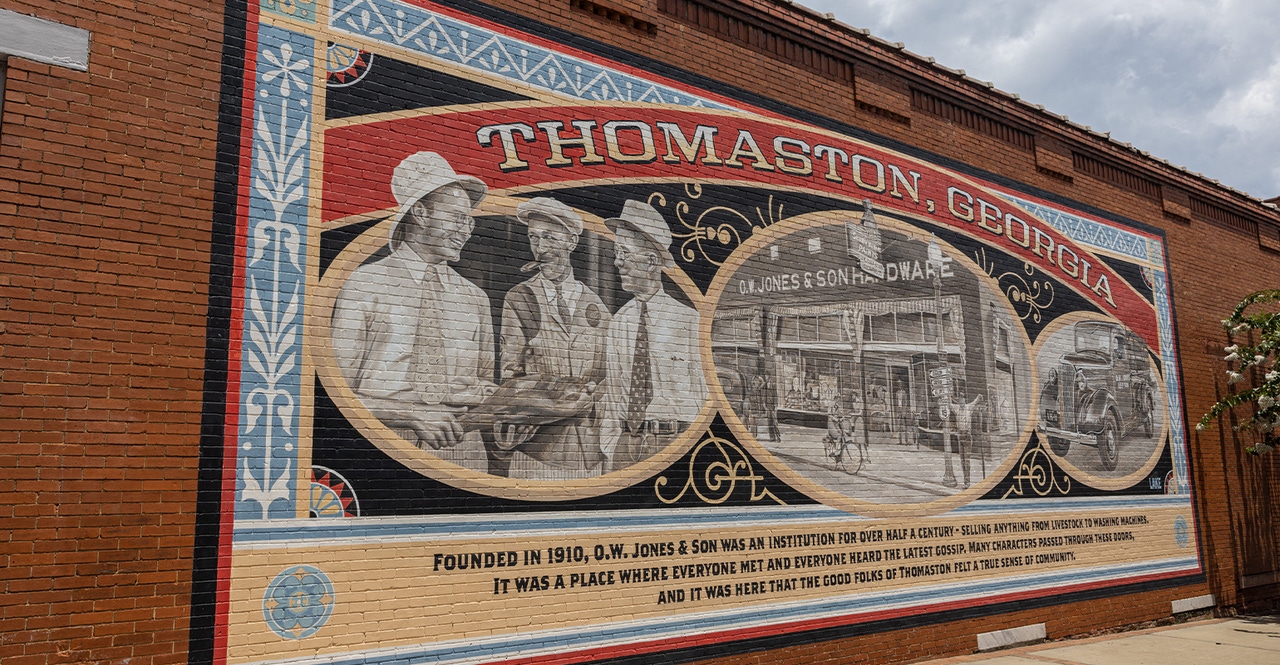

San Francisco-based Brightmark is preparing to launch its second chemical recycling plant leveraging pyrolysis to process mixed plastics—a $950 million project that will come to Thomaston, Georgia in Upson County. The first facility in Ashley, Indiana launched a couple of years ago, which Brightmark aims to scale to 100,000 tons of plastics a year; the ambition is to process four times that capacity in Upson County.

Brightmark calls its technology “plastics renewal,” which it bought from RES Polyflow who developed it to convert plastics to fuel. Bob Powell, Brightmark founder and CEO, says his team finetuned it to be able to make new plastic products from plastic waste (considered a higher-value use than fuel). He says it can process plastic nos. 1 through 7—even if they are mixed with food, paper, dirt, or other contaminants.

Plastics 1 through 7 include: polyethylene terephthalate (e.g., water bottles, soda bottles, and rope); high-density polyethylene (like milk and juice jugs, toys, and detergent bottles); polyvinyl chloride (piping, inflatable toys, bubble wrap); low-density polyethylene (bread bags, cling wrap, plastic grocery bags); polypropylene (yogurt and cottage cheese containers, medicine bottles, straws); polystyrene (Styrofoam containers, egg cartons, plastic utensils); and “miscellaneous plastics” (sunglasses, CDs, computer cases, etc).

Incoming baled materials will be separated, shred, and turned into pellets that will be heated in vessels and converted to pyrolysis oil that Brightmark says it will sell to companies to make feedstock for various plastic applications.

The team is eyeing multiple sourcing outlets from Georgia and the southeast U.S., including solid waste departments, private waste haulers, materials recovery facilities, and industrial companies that utilize plastics.

Powell cannot name suppliers but says he is in conversations with multiple potential partners –both companies looking for recycled content to meet their sustainability goals and generators and receivers of waste needing to dispose of it.

While there is no lack of plastic waste, it has yet to be captured in meaningful volumes, and mixed plastics especially remain a problem both to recover and process.

“Our current recycling rates are five percent for the 40 million tons of plastics we use yearly in the U.S. [down from a roughly 9 percent recycling rate, pre-COVID]. We are looking to resolve low recycling rates of plastics that are necessary for applications such as medical [supplies], computer, phone, and car components,” Powell says.

Recycling programs in the Southeast are among the country’s weakest, reports Eunomia Research & Consulting, who listed five states in that region (Alabama, Mississippi, South Carolina, Tennessee, and Louisiana) whose rates tank in the bottom 10. Nationwide, Eunomia identified potential to capitalize on $6.5 billion worth of materials annually currently lost to landfills.

Chemical recycling, which breaks down polymers to their basic building blocks to go into various products, has been the center of controversy in the world of plastics processing. Proponents say the technology fills a void of mechanical recycling by converting-hard-to-recycle polymers to new plastics, reducing dependence on virgin fossil. Critics call it an emissions-emitting, energy-intensive practice that has yet to be proven to work at a meaningful scale.

Brightmark reports its process will reduce carbon footprint by 39-139 percent over virgin plastic production (based on a lifecycle analysis by Environmental Clarity). It will save 82 percent of energy. And it will save 46 percent water, largely because of a “zero-liquid discharge system” whereby water from the conversion process will be recovered, reprocessed on site, and used again as input.

The Thomaston project moves forward after a two-year collaboration between Brightmark, local government, and businesses to iron out the vision. The deal is a significant step forward in what’s been a long journey for the company, beginning with several years of R&D and ongoing work to try and scale production in Ashley, which has been slower than projected.

Powell originally announced expectations to process 100,000 tons a year in Ashley beginning late 2020 or early 2021, but had reportedly processed only 2,000 tons total by April 2024, which could go into plastics or other applications.

Powell, a Georgia native, is focusing on the Peach state he says “because it is home for me— but more important is that Georgia is one of the country’s sustainability leaders and in a way that is friendly for businesses that are working to improve the environment. The governor has supported great environmental projects here,” he says.

Georgia has invested tens of billions in electric vehicle (EV) manufacturing, EV battery manufacturing, and charging stations while prioritizing other renewable energy projects, increasing its renewable power inventory by more than 93 percent since 2009, according to a state website. Following on corporates like Kia, Hyundai Motor, and Rivian setting up shop in Georgia, German copper recycler Aurubis and electronic waste recycler Igneo announced plans to operate plants in that state.

The Thomaston plastics recycling project is slated to generate nearly 200 manufacturing jobs—which is among reasons that the local government is in the pool of stakeholders backing the technology.

“We see a real opportunity to build a sustainable future together with Brightmark while leveraging our workforce of homegrown talent,” says Norman Allen, chairman, Upson County Board of Commissioners.

“During our year and a half-plus conversations it was clear that the company aims to positively impact the local economy [by investing millions in key infrastructure projects including utilities, roads, and rail access] while safeguarding our environment,” Allen says.

Brightmark was not always into plastics. The company launched in 2016 to run anaerobic digesters at dairy farms to make renewable natural gas from feedstock sourced from food processors. The team still operates digesters at 40 sites as it sets sights on expanding into this new niche.

Powell, who in an earlier day led solar companies (SunEdison, Solar Power Partners, and Pacific Gas & Electric), is looking beyond Georgia and Indiana, with hopeful plans to develop a pyrolysis plant in Parkes, New South Wales, Australia.

In the bigger scheme, he says, “We continue to explore opportunities for building similar plants across the U.S. and globally.”

About the Author

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)